New cure for hard to start Paso bikes

- higgy

- paso grand pooh-bah

- Posts: 3328

- Joined: Tue Jul 29, 2008 9:50 pm

- model: 907 I.E.

- year: 1992

- Location: Hilltown,Pennsylvania

- Contact:

Re: New cure for hard to start Paso bikes

All that said,the proof is in the pudding. No matter how well the starter wire is constructed or protected it will do nothing to prevent electrolytic migration which is the only issue here that matters in terms of durability. You must decide for yourself,do you want to do it once or do it over and over again. If you plan to take your duck down to the bone every 3 or 5 years go with the fully capable 8,7,6 or 5 gauge wire(if you can find them). If on the other hand you lack the talent or funding to DIY and you prefer to do it in a way that will last another 20 years of trouble free service 4 gauge is the only durable choice. 75 bucks is an rare price indeed!!@! Now all this is a moot point if you do yourself a favor and provide a mechanical way of disconnecting the battery. Otherwise you must remove the battery every time the bike will sit unused for more than a day or two.It is simple physics............

As Jon also has stated this guy is first rate in his research and from what I can see is honestly providing well constructed and DURABLE solutions to common(?) real world problems. Q.E.D.

On a side note I have a 2005 Nissan Frontier, I recently had to replace some very expensive but not rare components due to corrosion resulting from a commonly accepted wire gauge on the starter/charging circuit and electrolytic migration. I will present my case shortly.I have to find the time to provide the details in a fashion that all here can understand in black and white

As Jon also has stated this guy is first rate in his research and from what I can see is honestly providing well constructed and DURABLE solutions to common(?) real world problems. Q.E.D.

On a side note I have a 2005 Nissan Frontier, I recently had to replace some very expensive but not rare components due to corrosion resulting from a commonly accepted wire gauge on the starter/charging circuit and electrolytic migration. I will present my case shortly.I have to find the time to provide the details in a fashion that all here can understand in black and white

Ducati,making mechanics out of riders since 1946

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

-

Motolectric

- Posts: 15

- Joined: Tue Apr 27, 2010 2:28 am

- model: 900 SS

- year: 1995

- Location: SF Bay Area

- Contact:

Re: New cure for hard to start Paso bikes

Say Folks,higgy wrote: As Jon also has stated this guy is first rate in his research and from what I can see is honestly providing well constructed and DURABLE solutions to common(?) real world problems.

(hey, this ended up being a good bit longer than I had hoped it would be, sorry about that)

I wanted to say thanks for the positive comments about my products. I had hoped to participate in the dialog a bit more these last 2 weeks but I'm revamping 2 additional EAB/DDL kits into Motolectric multi-model releases (the fusebox and the lighting upgrade kit). That work, getting ready to launch Motolectric as a sponsor for ducati.ms and finalizing the development of an all new ignition upgrade kit means I've been a bit too busy to chime in.

I did want to give a bit better idea of what it is that I'm up to but do not want to have any forum members feel I am arguing with their point of view. There a good case to be made for what I'm doing and for some of the suggested alternatives.

So I'll just make a few bullet point type statements and hope it fuels further discussion about classic (and not so classic) bikes and keeping them reliable electrically.

- like most participants on the site I don't really like paying more than is needed for a product and especially don't like to pay a premium just to talk about it. The Motolectric kits are all designed to offer a final solution to a particular electrical problem. A solution that can be counted on to deliver 100% performance for the forseeable future. Since I have built the kits since 2002 I do have 8 years running of feedback from riders from 23+ countries and it really has been 100% satisfaction. The degree of satisfaction actually stretches to riders who had built their own uprated circuits and after buying the EAB/DDL kits they commented they wished they had paid the small bit extra, saved the time and aggravation they had making their own and had them done right the first time. For some multi-bike owners the first thing they do after buying another bike is order the DDL kits.

- pride of ownership does drive my decisions to some extent. I have about 30 years of having passersby and other riders comment on the Norton I built into a top end rider. It is not restored but every reasonable handling, reliability and appearance upgrade has been done the right way. I actually get riders offering to trade me more expensive bikes straight across. I have the same pride of ownership in my E900.

- so the above 2 points are the basis of what I am trying to do with the Motolectric kits. As we all know electrical issues are the most difficult for the layperson to deal with. Electrical problems can be intermittent and unlike other problems that can be muddled along on a trip (flat tire, uneven carburetion etc.) electrical issues can stop you dead in your tracks.

So the Motolectric kits are designed to be plug&play in that

no OEM wires ever need to be cut

all kits can be easily installed by a layperson

the bike can be returned to box stock condition if needed for collectible/concours reasons

all circuits are sealed from the environment as much as possible (to about 99.9%)

circuits can be easily removed from the bike to be used on a subsequent bike

all circuits are designed for long term use and acknowledge the inevitable degradation of current flow capability by being overspec at the outset effectively extending 100% or near 100% performance far into the future.

So I could go on and on but the final point is that I am aiming to establish the brand Motolectric as being the equivalent in the electrical field as Ohlins is in the suspension field. That is, a true asset to the bike. If someone is thinking of buying a used motorcycle and it has a brand X aftermarket shock on it the shock adds no real value above that of an OEM shock. The owner is probably not going to able to recoup any of the cost of the brand X shock. But if the shock is an Ohlins then the seller is going to be able to ask a higher price as the Ohlin is a known high quality product and so his cost of ownership for the Ohlins is actually lower than it would appear. If the owner can recoup 50% of the cost and got use from the Ohlin then the true cost of ownership was quite small.

My goal is to establish Motolectric as the standard for high quality reliable electrical upgrades such that it becomes common that if a person is selling their bike and list that some or all of the Motolectric upgrades have been installed that the bike has a higher value than if stock or if equiped with unknown brand or owner fabricated upgrades. If you look at the equation in that light you will understand that my kits are actually cheaper than doing it yourself. On the E900 talk list I sponsor it is very common now for riders looking to sell their bike to list that they have the DDL electrical kits installed. And they ask a higher price.

I will shortly announce the

FLOBox - full light output lighting upgrade kit, fits 90% of all bikes on the road

FuzeTrax - adds 6 key-switched fuse tracks to any bike.

Chronotron - high speed current storage module that synchronizes the electrical and ignition systems

I'll drop a note back to this forum when I launch those products and also when the Motolectric ducati.ms forum launches in about a week. I will be active on that forum on a daily basis.

Thanks,

Michael Heth

TOTB (the one to blame)

Motolectric

- higgy

- paso grand pooh-bah

- Posts: 3328

- Joined: Tue Jul 29, 2008 9:50 pm

- model: 907 I.E.

- year: 1992

- Location: Hilltown,Pennsylvania

- Contact:

Re: New cure for hard to start Paso bikes

just placed an order for two of these kits.

One for the 907 which needs it desperately and one for the 906,figured might as well

One for the 907 which needs it desperately and one for the 906,figured might as well

Ducati,making mechanics out of riders since 1946

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

- randtcastell

- Posts: 356

- Joined: Fri Nov 13, 2009 4:33 pm

- model: 750 Paso

- year: 1987

- Location: San Francisco Bay, California USA

- Contact:

Re: New cure for hard to start Paso bikes

I plan on purchasing one as well. After reading this really good discussion I can make an informed decision about the usefulness of the monster cable solution.

I am contemplating a new regulator purchase. May I ask you gentlemen about your opinion regarding which regulator is correct for a 750 Paso:

http://shop.bevelheaven.com/detail.aspx?ID=723

or

http://shop.bevelheaven.com/detail.aspx?ID=1360.

I prefer the price of the first, but my existing regulator looks similar to the second, but with wires rather than a built in connector.

Thank you all in advance for your thoughts and your time.

-Randy.

I am contemplating a new regulator purchase. May I ask you gentlemen about your opinion regarding which regulator is correct for a 750 Paso:

http://shop.bevelheaven.com/detail.aspx?ID=723

or

http://shop.bevelheaven.com/detail.aspx?ID=1360.

I prefer the price of the first, but my existing regulator looks similar to the second, but with wires rather than a built in connector.

Thank you all in advance for your thoughts and your time.

-Randy.

1987 Ducati P750

1973 Honda CB450

2022 KTM RC390

1973 Honda CB450

2022 KTM RC390

- paso750

- paso grand pooh-bah

- Posts: 5558

- Joined: Sun Jul 18, 2004 12:00 am

- model: 750 Paso

- year: 1987

- Location: southern Germany

Re: New cure for hard to start Paso bikes

Randy, whatever reg/rec you buy, get an aftermarket not the original !

In most cases you`ll have to modify the connectors, but that`s definetely worth it.

There`s also Electrex/Electrosport btw. http://www.electrosport.com/street-bike ... ifier.html

or

G.

edit: this seems to be the cheapest one:

http://www.psep.biz/store/ducati_motorc ... ulator.htm

In most cases you`ll have to modify the connectors, but that`s definetely worth it.

There`s also Electrex/Electrosport btw. http://www.electrosport.com/street-bike ... ifier.html

or

as mentioned in the interchangeability listHonda CB250/400N Superdream, CM450 or CX500 (Shindengen part number: SH 232 127 - for many non-fuel injected Ducatis).

G.

edit: this seems to be the cheapest one:

http://www.psep.biz/store/ducati_motorc ... ulator.htm

- micklm

- Posts: 103

- Joined: Fri Jun 05, 2009 8:53 pm

- model: 906 Paso

- year: 1989

- Location: Taranaki, New Zealand

Re: New cure for hard to start Paso bikes

Hi all,

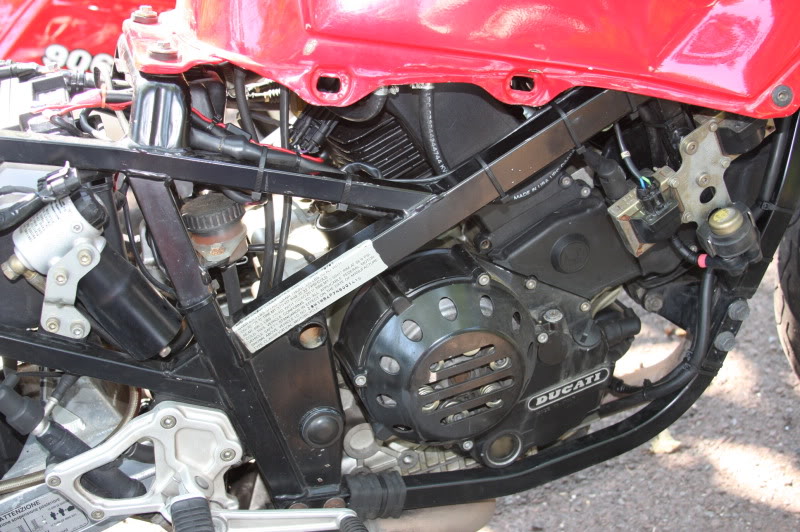

I've just fitted one of these kits to my 906 and the bike starts first time, every time now. It has made a notable difference and I no longer hold my breath while pressing the starter. It's gotten to the point I expect it to fire up straight away! (can't say that for any other Ducati I've owned)

All cable lengths were perfect and the build quality is very high in my opinion. Certainly I could not make something of this gauge at home.

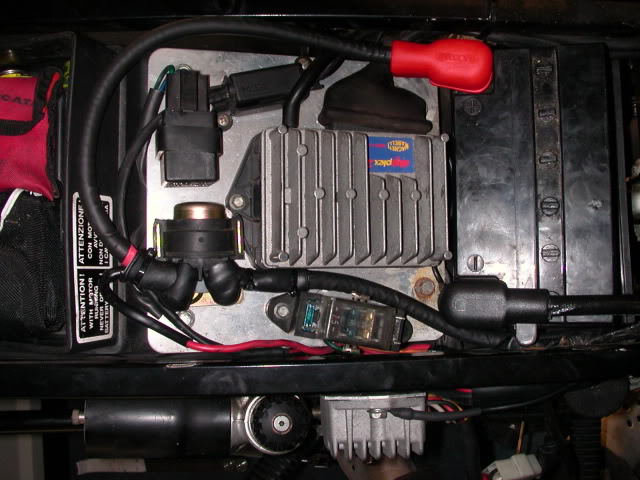

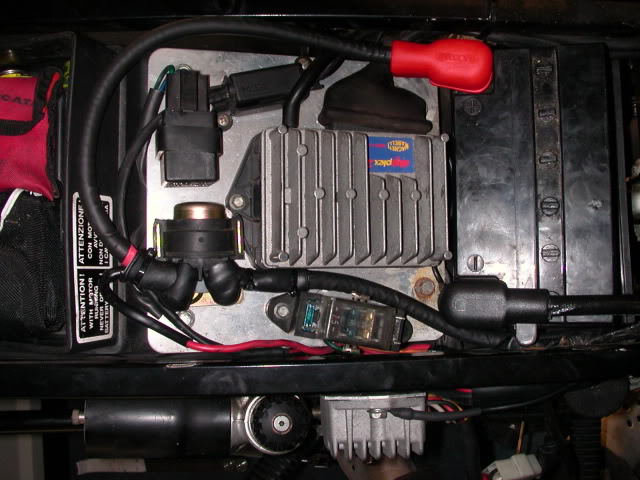

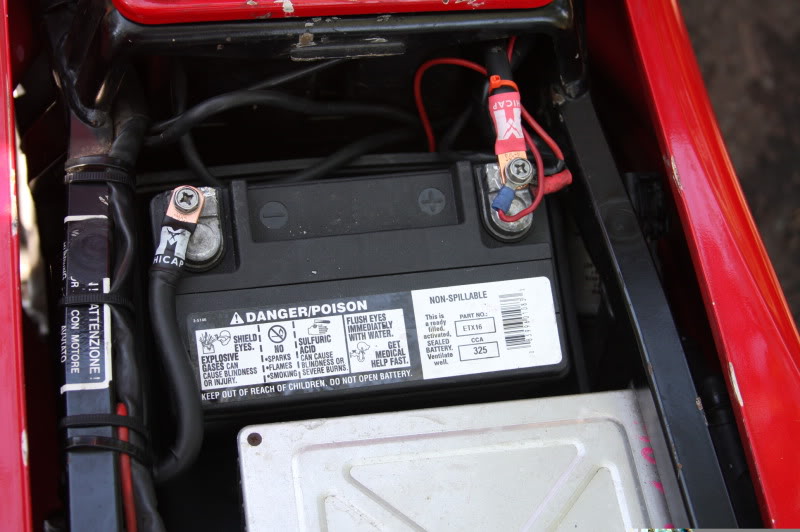

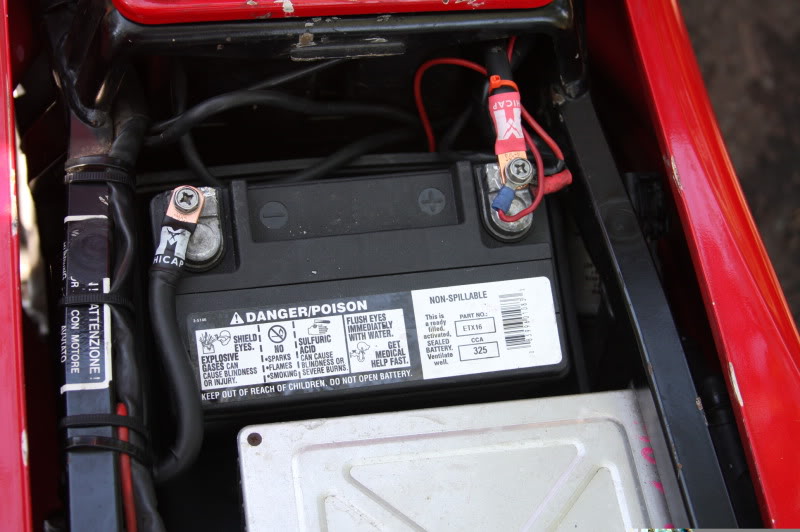

A couple of issue with fitment - these cables are indeed 'monster' big (as Gerhard warned me). Think hose size rather than wire size. They are therefere not so flexible as the OEM wiring. Sound obvious, but can be more of an issue for cable routing. This may be specific to the 906 bikes as the digiplex ignition unit takes up alot of room under the seat.

The starter wiring routing I ended up using under the seat was slightly different than OEM as I decided it fit better my way with the stiffer, thicker cables. I also made use of the fact I can either top mount or back mount to the terminals on my battery (top mount was better for me).

You could bolt on the kit as it comes with the OEM routing, no problems. But I would advise some thinking as you can reduce the stress on the cables and all the stuff they put pressure on (e.g. the fusebox). From memory I flipped the solenoid over and shifted one of the fusebox mounting bolts slightly.

I also decided to use different rubber boots on the cables at the solenoid and battery to fit all the extra wires in easier with the thicker stater cables.

As a side note, perhaps the main benefit of the upgrade was me discovering that other parts of my wiring loom, especially around the fusebox, were completely corroded and almost falling apart. Amazing what you find when you look! As a result of this the final version of my wiring upgrade had a new (weatherproof) fusebox relocated where the old Duoshock remote resevoir is in the photo (I've changed the shock to a P750 Ohlins type with a stiffer spring for the heavier 906).

Cheers,

Mick

I've just fitted one of these kits to my 906 and the bike starts first time, every time now. It has made a notable difference and I no longer hold my breath while pressing the starter. It's gotten to the point I expect it to fire up straight away! (can't say that for any other Ducati I've owned)

All cable lengths were perfect and the build quality is very high in my opinion. Certainly I could not make something of this gauge at home.

A couple of issue with fitment - these cables are indeed 'monster' big (as Gerhard warned me). Think hose size rather than wire size. They are therefere not so flexible as the OEM wiring. Sound obvious, but can be more of an issue for cable routing. This may be specific to the 906 bikes as the digiplex ignition unit takes up alot of room under the seat.

The starter wiring routing I ended up using under the seat was slightly different than OEM as I decided it fit better my way with the stiffer, thicker cables. I also made use of the fact I can either top mount or back mount to the terminals on my battery (top mount was better for me).

You could bolt on the kit as it comes with the OEM routing, no problems. But I would advise some thinking as you can reduce the stress on the cables and all the stuff they put pressure on (e.g. the fusebox). From memory I flipped the solenoid over and shifted one of the fusebox mounting bolts slightly.

I also decided to use different rubber boots on the cables at the solenoid and battery to fit all the extra wires in easier with the thicker stater cables.

As a side note, perhaps the main benefit of the upgrade was me discovering that other parts of my wiring loom, especially around the fusebox, were completely corroded and almost falling apart. Amazing what you find when you look! As a result of this the final version of my wiring upgrade had a new (weatherproof) fusebox relocated where the old Duoshock remote resevoir is in the photo (I've changed the shock to a P750 Ohlins type with a stiffer spring for the heavier 906).

Cheers,

Mick

Last edited by micklm on Wed Dec 19, 2012 9:39 am, edited 1 time in total.

906 Paso 1989 w/ 17in wheels

- higgy

- paso grand pooh-bah

- Posts: 3328

- Joined: Tue Jul 29, 2008 9:50 pm

- model: 907 I.E.

- year: 1992

- Location: Hilltown,Pennsylvania

- Contact:

Re: New cure for hard to start Paso bikes

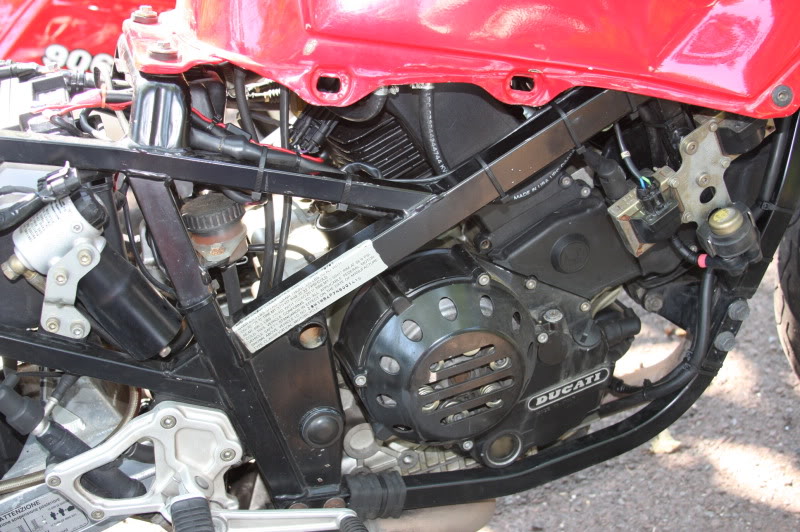

Kits arrived and I installed the 907 kit. Very nice. Only had to take a file to the connectors at the soleniod so that it all could fit with the covers on.no big deal

It was a tight fit on the solenoid,after a little filing it fit perfectly

Here is the rest of the pics , the kit and the install

The bolt is for grounding directly to the engine(where it belongs anyway ) for those with issues on the original ground location

) for those with issues on the original ground location

Mike provides a bolt to ground the strap here if you need

It was a tight fit on the solenoid,after a little filing it fit perfectly

Here is the rest of the pics , the kit and the install

The bolt is for grounding directly to the engine(where it belongs anyway

Mike provides a bolt to ground the strap here if you need

Ducati,making mechanics out of riders since 1946

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

Re: New cure for hard to start Paso bikes

Interesting topic.

I have to say that whenever I encountered starting issues it was always due to:

- poor connections ( oxydized poles on batteries starter relais, starter motor)

- end of life starter motor (usually brushes need replacing and rotor collar needs a good cleaning)

- end of life starter relais.

as for points 2&3 there is very little we can do, overhauling and replacement is the only solution.

Unfortunately the poor connections are something we have to live with when the bikes (or cars) are used in harsh environments or simply because they get old.

The average PASO is around 20 years therefore it is most likely it will be affected in the electrics compartment and very often it is simply because the connections are overlooked.

wd40 is my best friend...but there are wonderful products out there suitable for cleaning and lubricating properly the contacts.

I truly believe the kit proposed works ( I find it a little bit pricey, but i guess you pay for the convenience of having a "kit" taylor made) , although I am preatty sure that just by disassembling, cleaning, lubricating and reassembling the old wiring it would make a noticeable difference.

To give an idea of how important are the connections.... last year I took of the 907 for a ride and got stranded with all the electrics off.

The first though was that the battery failed (regulator failure, battery cooked) but before panicking I started by pulling/moving the cables around the battery (it was the last thing i touched before leaving my garage) noticing that the positive was extremely hot and suddently there was life in the circuits!

The issue? I couldnt believe it.... it was due to the oxidation of the battery pole.

I always disconnect the battery when I do not use the bike for a while and in the rush of going out for a ride I tightened the positive without cleaning & lubricating the contact area and that was more than enough to stop all the electrics.

Sometimes oxydation creates "hotspots" when the current flows, these hotspots have high resistance and the more current passes through the hotter they get...to the point that there is a noticeable voltage at the end of the cable which can be enough to cause electric devices to fail.

I have to say that whenever I encountered starting issues it was always due to:

- poor connections ( oxydized poles on batteries starter relais, starter motor)

- end of life starter motor (usually brushes need replacing and rotor collar needs a good cleaning)

- end of life starter relais.

as for points 2&3 there is very little we can do, overhauling and replacement is the only solution.

Unfortunately the poor connections are something we have to live with when the bikes (or cars) are used in harsh environments or simply because they get old.

The average PASO is around 20 years therefore it is most likely it will be affected in the electrics compartment and very often it is simply because the connections are overlooked.

wd40 is my best friend...but there are wonderful products out there suitable for cleaning and lubricating properly the contacts.

I truly believe the kit proposed works ( I find it a little bit pricey, but i guess you pay for the convenience of having a "kit" taylor made) , although I am preatty sure that just by disassembling, cleaning, lubricating and reassembling the old wiring it would make a noticeable difference.

To give an idea of how important are the connections.... last year I took of the 907 for a ride and got stranded with all the electrics off.

The first though was that the battery failed (regulator failure, battery cooked) but before panicking I started by pulling/moving the cables around the battery (it was the last thing i touched before leaving my garage) noticing that the positive was extremely hot and suddently there was life in the circuits!

The issue? I couldnt believe it.... it was due to the oxidation of the battery pole.

I always disconnect the battery when I do not use the bike for a while and in the rush of going out for a ride I tightened the positive without cleaning & lubricating the contact area and that was more than enough to stop all the electrics.

Sometimes oxydation creates "hotspots" when the current flows, these hotspots have high resistance and the more current passes through the hotter they get...to the point that there is a noticeable voltage at the end of the cable which can be enough to cause electric devices to fail.

- paso750

- paso grand pooh-bah

- Posts: 5558

- Joined: Sun Jul 18, 2004 12:00 am

- model: 750 Paso

- year: 1987

- Location: southern Germany

Re: New cure for hard to start Paso bikes

swapping the coils with some aftermarket like Dyna (green) makes quite a difference in firing the bike up. I found it an overall improvement. Idle is a bit better and throttle response also while here the felt difference is not that big.

G.

G.

- jcslocum

- paso grand pooh-bah

- Posts: 1714

- Joined: Mon Jul 19, 2004 12:00 am

- model: 750 Paso

- year: 1988

- Location: Eastern Shore, MD

- Contact:

Re: New cure for hard to start Paso bikes

Those cables are HUGE!

A good looking kit. I'm glad it's available for us to improve the electric system of our Paso's.

A good looking kit. I'm glad it's available for us to improve the electric system of our Paso's.

- higgy

- paso grand pooh-bah

- Posts: 3328

- Joined: Tue Jul 29, 2008 9:50 pm

- model: 907 I.E.

- year: 1992

- Location: Hilltown,Pennsylvania

- Contact:

Re: New cure for hard to start Paso bikes

So you have not sold yours as yetour Paso's.

Last edited by higgy on Wed Sep 22, 2010 1:56 am, edited 1 time in total.

Ducati,making mechanics out of riders since 1946

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

- higgy

- paso grand pooh-bah

- Posts: 3328

- Joined: Tue Jul 29, 2008 9:50 pm

- model: 907 I.E.

- year: 1992

- Location: Hilltown,Pennsylvania

- Contact:

Re: New cure for hard to start Paso bikes

I truly believe the kit proposed works ( I find it a little bit pricey, but i guess you pay for the convenience of having a "kit" taylor made) , although I am preatty sure that just by disassembling, cleaning, lubricating and reassembling the old wiring it would make a noticeable difference.

Hi Anglix

Actually, 75 dollars is not "that far off of the price" of all the components these days. But the real expense is the crimpers.

If you have the proper crimpers, I agree 75 bucks is high but still a bargain

It is a very nice kit none the less.

Last edited by higgy on Wed Sep 22, 2010 12:20 am, edited 1 time in total.

Ducati,making mechanics out of riders since 1946

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

-

Motolectric

- Posts: 15

- Joined: Tue Apr 27, 2010 2:28 am

- model: 900 SS

- year: 1995

- Location: SF Bay Area

- Contact:

Re: New cure for hard to start Paso bikes

Say Folks, since I am just now creating some documentation for my site addressing the above topics I thought I would chime in here.higgy wrote:I truly believe the kit proposed works ( I find it a little bit pricey, but i guess you pay for the convenience of having a "kit" taylor made) , although I am preatty sure that just by disassembling, cleaning, lubricating and reassembling the old wiring it would make a noticeable difference.

Actually, 75 dollars is not "that far off of the price" of all the components these days. But the real expense is the crimpers.

If you have the proper crimpers, I agree 75 bucks is high.

The first point is that with fixed value DC electrical circuits there is a "formula" which basically states how the circuit should work.

1 - You have the electrical supply of 12.85 volts (the battery)

2 - You have the electrical consumer which wants 700 watts (the Denso .7 kilowatt starter motor)

3 - You have the desired end result (the starter turns over the engine and the bike starts)

The above formula says to make the circuit happy we have to get right about 54 amperes to the starter.

Now if you have the very smallest amount of resistance possible in the connecting wire and terminals, what happens?

Well, with the HICAP kit in place, the engine starts up in somewhere between .3 to 1.5 seconds on virtually every bike out there. Even big 1198s with higher than stock compression (like 12 to 1 etc.) start in about 1.5 seconds (down from 4-7+ seconds).

And since the circuit is a fixed circuit (we can't change how much energy the starter asks for etc.) the above scenario defines the true (originally engineered) performance of the circuit. ( I use the term energy and not current because as the voltage goes down the amount of current required goes up, at 12.2 volts the current has to be 57.37 but if you did have 12.85 then you only need 54.47, both equal the same amount of energy and will get the same job done). The 12.85 volts is open circuit meaning with no real load. In my videos you will see the actual working voltage drop down into 12.2-12.4 as soon as the key is turned on and the battery has to start doing some work.

So, if we have the 12.85 volts (modern AGM batteries when measured "open circuit" are now all at about 12.85 when fully charged) and the starter motor is not hosed, than anything longer than about 1 second (on average) is excess wear on some pretty expensive parts of the motorcycle. I had thought that starters were about $300 but was just told by a guy who had to get a new one that they are actually $600 - he was pretty happy that it tanked within his 2 year warranty. That's right, his 2 year old Multi Strada ate a battery and a starter within 2 years due to his having to crank the starter so long to get the bike to fire up.

So the point of the HICAP kits and why they are engineered the way they are and with the particular raw components is to get the resistance to be the lowest possible and to keep it there for as long as possible.

If you're wondering where the energy went if it wasn't getting to the starter - it was being turned into heat at each of the terminations and along the wire length. If your bike is slow to start, you can feel the heat in the leads as it cranks around. The terminals will actually get hot.

And Higgy is right, you just cannot get the very high pressure needed to really compressed the metals together using anything other than a professional level crimping tool. Trying to crush things in your vice does not get you there.

As for the pricing on the kits, it is actually based on a normal business formula for hard goods. It takes into account the cost of materials, cost of paid labor to make, package etc. I have looked at every possible way to get the price lower and the only way to do it is to really cheap out on the parts (source crap from China etc.) and not do the little hidden things that I do to make the circuit last so long. And that's not the way I go, it's do it right or I won't do it.

The list price on the (Paso) HICAP is $90 for a dealer to sell at and I sell them direct to rider/mechanics at $75 and pay the shipping. The kits are priced to be sold through the dealer network to allow them to help the 50%+ of the Ducati owners who do not do their own work. This way the dealer can make some money and feed his kids and (hopefully) stay in the business so the rider can have a reliable bike. (My county has lost 4 motorcycle dealerships in the last 2 years, we're down to 1 in the whole county).

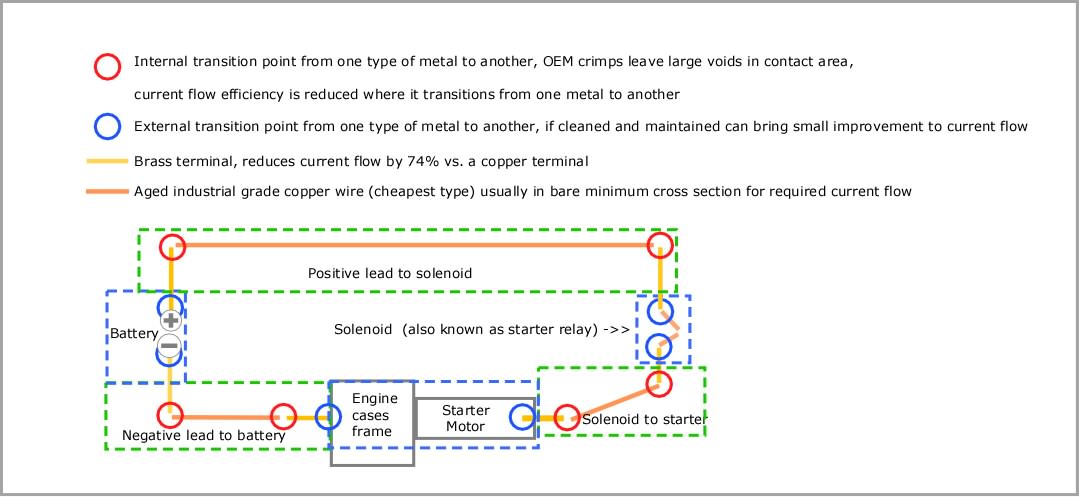

To help folks understand the finer points I have a couple of images below (the graphic is a work in progress and still kinda rough).

The parts of the starting circuit in the blue boxes are fixed and my kit cannot improve them. The parts in the green boxes are what is upgraded in a HICAP kit. As I show, although you can go ahead and clean all the connections there is a high portion of the circuit that you cannot clean and the cleaning effort will be pretty close to the same amount of work as installing the HICAP. And then there is the fact that the cleaning will just not get you down into the 1 second range that will maximize the life of your starting system.

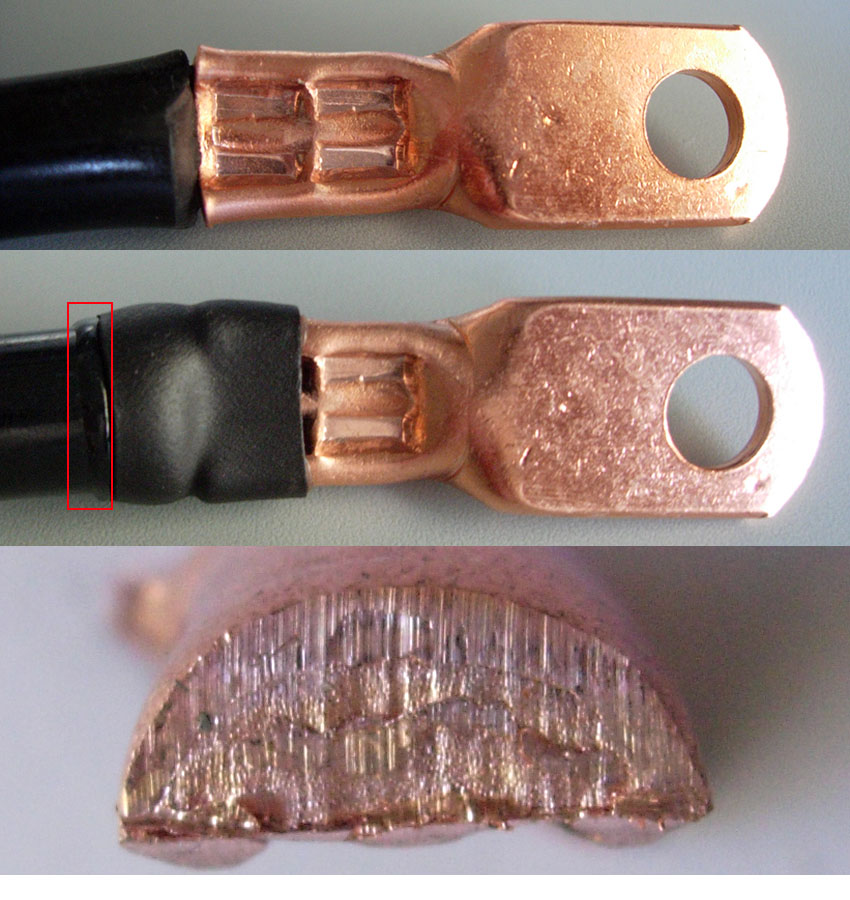

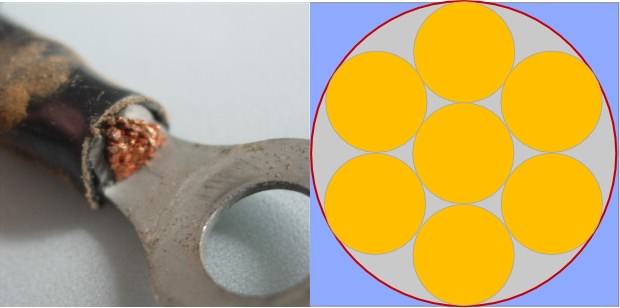

The next graphic shows the hidden steps taken to maximize the performance life of the HICAP product. The electrical industry standard for crimping a 4 GA cable to a terminal is 1 crimp using a high pressure tool like I do. But I do 2 crimps so that I completely crush the copper together to evaculate all of the air in the terminal. What I have left is as close to a solid copper termination as possible. I then use a double wall heat shrink that is lined with a hot melt adhesive. As it shrinks it conforms to the terminal/insulation juncture. The hot melt seals the juncture against the environment and also reinforces the terminal edge and the outer shrink that is the last layer of the lead (also increases the heat resistance to about 220+F).

The next image is of a terminal that I cut in half, as you can see the 1000 strands of copper are crushed together with virtually no gaps of any type. Over time the copper with fuse together and blur the point where there was wire and there was solid terminal.

Finally the last images illustrate the problem of the OEM transitions from their low strand count - large gauge wire strands and the terminal surface and how it leaves gaps in the contact area. Copper is a fairly soft metal but it does get stiff if it is thick. The 37 GA strands in the HICAP are extremely thin and bend/crush together when crimped causing the gaps between the individual strands to be compressed or eliminated. Not so with the thicker strands of conventional industrial grade wire. The 37 GA designation of the HICAP individual wire strands means the copper went through reducing dies 37 times. Conventional wire of the same gauge will have a strand count that is much lower although the cross section would be the same. Conventional wire costs less in part because they don't run it through reducing dies so many times (which costs money) and so the strands are thicker. But then the OEM wire is really in the 6 gauge range, the HICAP uses 4 gauge.

As I mentioned in a prior post I welcome any and all questions or concerns about these types of things because they allow me to work through educating folks who come to my site.

I want to thank Higgy for the feedback he gave me in emails and for sending me the photos of his install and for posting them here in the forum.

Thanks,

M./

- higgy

- paso grand pooh-bah

- Posts: 3328

- Joined: Tue Jul 29, 2008 9:50 pm

- model: 907 I.E.

- year: 1992

- Location: Hilltown,Pennsylvania

- Contact:

Re: New cure for hard to start Paso bikes

You are most welcome

One comment to add, and I have made it here before, in terms of conductance, and thats is what it is all about, Multi-strand wires and solid core wires all tend to "do the work" on the outside surface.(G are you paying attention )

)

so what does that mean to a Ducatista simple, bigger is better

simple, bigger is better

One comment to add, and I have made it here before, in terms of conductance, and thats is what it is all about, Multi-strand wires and solid core wires all tend to "do the work" on the outside surface.(G are you paying attention

so what does that mean to a Ducatista

Ducati,making mechanics out of riders since 1946

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

- scimmione

- Posts: 65

- Joined: Sun Jul 18, 2010 1:56 am

- model: 750 Paso

- year: 1987

- Location: East Bay, SF Bay Area

Re: New cure for hard to start Paso bikes

Higgy: I've got to chime in on the electrolytic migration comments. Wire size will help reduce electrolytic migration in a battery if there is a reduction in amps with a larger dia wire. Wire corrosion can increase electrolytic migration in a battery if amp draw in the circuit goes up as a result of the corrosion, but wire corrosion itself is not caused by electrolytic migration, but by oxidation of the wire itself.

Wish I'd bought the 990 years ago