Page 2 of 2

Re: Project - Nudo Nuovo

Posted: Wed Dec 04, 2013 5:08 am

by ducinthebay

Update:

After trolling e-bay for a few years, I now have a stock 1990 750 Sport swing arm. Clean, and straight, and no cracks.

I pulled off my my modified steel SS swing arm, and weighed it, and a stock 900ss aluminum swing arm, and the stock one.

- Stock 750 Sport 6.5 lbs

- Stock 900 SS aluminum 8.5 lbs.

- Modified steel SS swing arm 12.5 lbs.

Needless to say, I put the stock swing arm on the project bike. Pictures coming soon.

Cheers, Phil

Re: Project - Nudo Nuovo

Posted: Thu Dec 05, 2013 9:49 pm

by ducinthebay

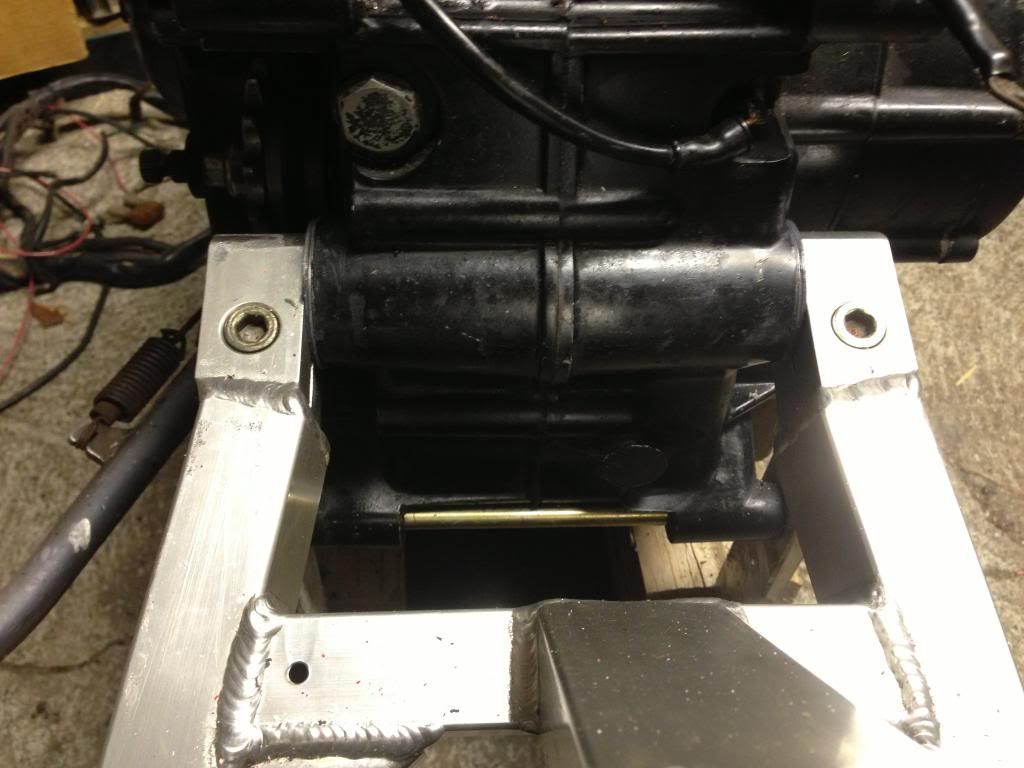

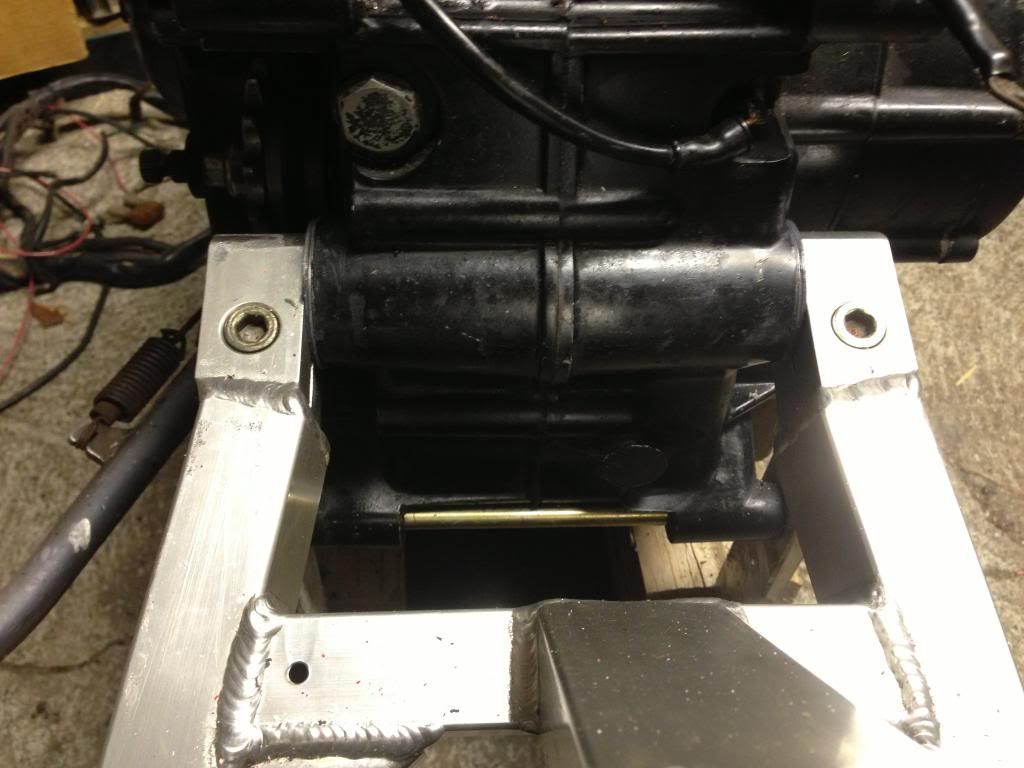

Ok, here is the most recent progress. I have a swing arm with a perfectly aligned rear wheel, and brakes too.

Stock 750 Sport swing arm attached to the engine. New seals installed, and reshimmed as tight as I can make it, with Moly grease on the shims. Brand new pivot pin from the P.O.

Rear wheel is from a Sport Classic, Caliper and carrier from a newer Monster 696. After market rear rotor.

Fitting a 25mm axled rear wheel to a 17mm axled swingarm was a challenge. Ended up using an old ST2 axle, that happened to be 25mm outside, and 17mm inside. Cut it short, and inserted into the wheel, sprocket carrier and caliper hanger. Then run the 17mm axle inside all of that. A bit of extra weight, but the simplest way forward.

Sprocket has been drilled a bit, and mounted to a 750 SS carrier to keep the chain line inboard as much as possible.

I'll take a photo of my C/s Sprocket set up, and tools that helped get me a perfect chain line. (next post)

Now I need to fashion some sort of chain slider, as the swing arm didn't come with one, and the seller didn't have one. Can someone post me a picture so I can see what it should look like?

Cheers, Phil

Re: Project - Nudo Nuovo

Posted: Thu Dec 05, 2013 10:09 pm

by Maico88

Here are some pics of the slider on my Sport.

Hope this helps. In a few days I will have time to remove the slider and take pics and give you dimensions.

Re: Project - Nudo Nuovo

Posted: Thu Dec 05, 2013 10:44 pm

by paso750

like the one for the Paso it doesn`t exist anymore so fingers crossed you find one

Re: Project - Nudo Nuovo

Posted: Thu Dec 05, 2013 11:15 pm

by ducinthebay

Thanks for the photos. I have a few sliders from later model SS, both 750 and 900 (different chain lines) I'll be modifying one of those. I see some plastic welding in my future. My chain line isn't in the same spot as the old one, so a stock slider won't help me now anyway, especially now that I see the photo. My chain line is now much further outboard.

Cheers, Phil

Re: Project - Nudo Nuovo

Posted: Mon Dec 09, 2013 4:14 am

by ducinthebay

Update - Chain Line alignment

Any time you put on a different wheel than was intended, you have the challenge of the chain line. If its off, the chain and sprockets will wear quickly, and there is always the chance of catastrophic chain failure. Heres how I aligned the chain with a Sport Classic wheel on 750 Sport.

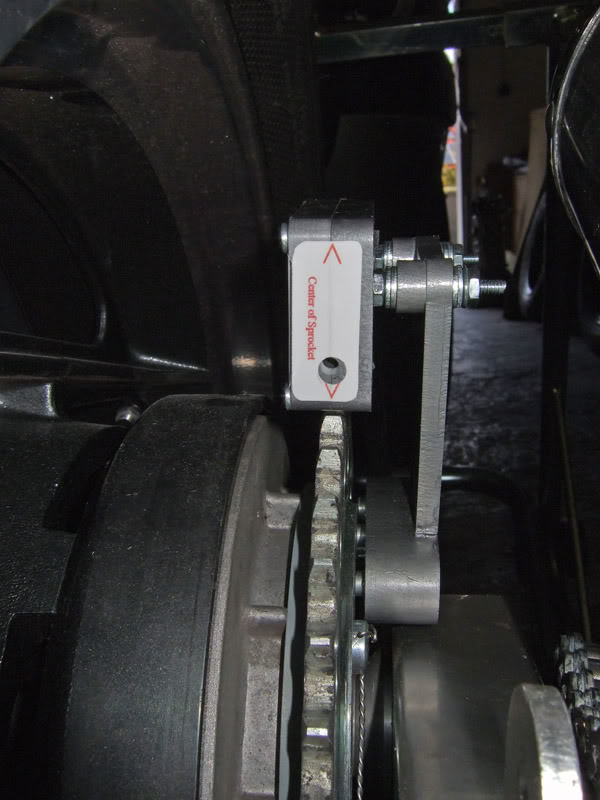

Start with a wheel alignment tool, to ensure that your wheel is square in the swing arm. (rear axle is parallel to the swing arm pivot pin)

I modified this one to fit into the swing arm pivot pin.

Here it is on the right side of the bike.

Then, try it on the other side to see that they are the same.

Once you have the wheel square, then you can see where the rear sprocket is aimed, and hopefully its at your front sprocket.

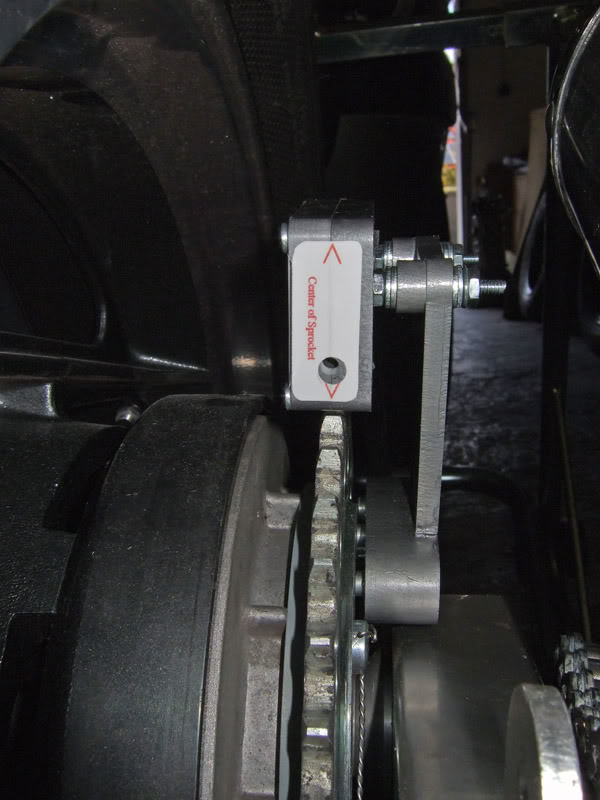

I used a laser tool that works pretty good.

I checked both sides of the sprocket just to be sure.

In my case, I used a sprocket carrier from a 750SS and a big offset front sprocket that has a washer welded onto the outside. So I brought the chain line in as much as I could on the wheel, and as far out as I could with the C/S sprocket. I got lucky that they aligned perfectly.

So, you can see that the stock chain slider won't work. I'm cutting up one from a 750SS and reshaping it. I'll let you know how it works.

Cheers,

Phil

Re: Project - Nudo Nuovo

Posted: Mon Dec 09, 2013 10:42 am

by paso750

Phil,

the kind of work you`re doing interests me as those are the kinds of things I like to do, too.

So please don`t mind that I have several questions:

- that alignment tool has a conical endpiece and the rod doesn`t seem very thick. Isn´t there a risk that it bends when pushing the conical endpiece in the axle falsifying the result ? (it seems to have a slight bend in the third pic)

- also did you set the chain tension adjusters to the 0 position or fully to the front before tightening the axle and checking alignment ?

- what reference did you use to center the swingarm and rear wheel the front wheel, the frame or the engine ? Often an engine doesn`t sit centered in the frame and hence the rear wheel is offset in the swingarm to align with the front wheel or the whole swingarm is slightly offset.

- that CAT laser, how does that work, what reference do you see at the front sprocket ? It interests me because the one I have comes with a bracket to center it on the sprocket so you see the laserpoint exactly on the teeth of the front sprocket. I was thinking of getting that CAT tool before I found this (cheaper) one.

G.

Re: Project - Nudo Nuovo

Posted: Mon Dec 09, 2013 2:55 pm

by ducinthebay

paso750 wrote:Phil,

I have several questions:

- that alignment tool has a conical endpiece and the rod doesn`t seem very thick. Isn´t there a risk that it bends when pushing the conical endpiece in the axle falsifying the result ? (it seems to have a slight bend in the third pic)

G.

Yeah, its a bit flimsy bit of kit, but you can get the feel for it if its the same both sides. You could also measure it, if you had a decent reference point.

paso750 wrote:

- also did you set the chain tension adjusters to the 0 position or fully to the front before tightening the axle and checking alignment ?

G.

I set the chain adjuster to the middle of the range so that I can also confirm the hash marks on the swing arm. This one was pretty close, but others have been off a bit.

paso750 wrote:

- what reference did you use to center the swingarm and rear wheel the front wheel, the frame or the engine ? Often an engine doesn`t sit centered in the frame and hence the rear wheel is offset in the swingarm to align with the front wheel or the whole swingarm is slightly offset.

G.

Since I am using a stock swing arm, I didn't do anything to shift that left or right, and the tire is pretty much centered in the swing arm, so I called it good. Not scientific, but close enough.

paso750 wrote:

- that CAT laser, how does that work, what reference do you see at the front sprocket ? It interests me because the one I have comes with a bracket to center it on the sprocket so you see the laserpoint exactly on the teeth of the front sprocket. I was thinking of getting that CAT tool before I found this (cheaper) one.

G.

The CAT laser shows a dot straight forward that is about the width of the outside plates of your chain. If I had a chain on, it would shine a laser point right along it. I used a bit of paper with a notch cut into it and placed it on the front sprocket. I then confirmed that the laser point was the same distance on each side. Again, close enough is good enough. I'm within 1mm or so.

Out of interest, I should do the same to my ST4s just to see if that rear wheel is square. I took no measurements of the frame or rest of the bike, as its not yet built up, and i just got the frame straightened.

Cheers, Phil

Re: Project - Nudo Nuovo

Posted: Mon Dec 09, 2013 3:35 pm

by paso750

thanks

Re: Project - Nudo Nuovo

Posted: Sat Dec 21, 2013 5:12 pm

by ducinthebay

Update.

Chain slider needed to be modified/made, and some detail on the odd front sprocket.

I used this sprocket that has a deep splined section, and a welded washer on the outside. The countershaft has an 8mm tapped hole in it already, that accepts a bolt. The bolt can not be simply tightened onto the sprocket, as the rocking back and forth of the sprocket on the shaft will loosen up your bolt in a few short miles, and yes, I have confirmed it. A shoulder bolt would also work, but I couldn't find one in the range that would work.

So, I made a spacer that allows me to torque the bolt tight, and allows the sprocket to float, but just a little bit. I included a warpy washer to take up slack. Here is the sprocket on the shaft with the bolt tightened, and the warpy washer inserted to show that I have just enough free play. The step on the spacer is just slightly larger than the thickness of the washer that is welded on the sprocket. The bolt has plenty of Loctite on it, and a locking washer.

and one more shot to show all the bits before I installed them.

The chain line is now perfect from front to back, but the stock slider would be useless, (even if I did have one) since the chain line moved outboard. I took one from a later model 750 SS (different from the 900SS) and cut it up, and welded it. I simply bolted in place, and use a soldering iron to melt the junction. A little filing to finish it off and called it good.

Of course, I simply aligned the slider to the chain, then fixed to that position.

Master link showed up in the mail today, so I should have a chain on it later today.

Cheers, Phil

Re: Project - Nudo Nuovo

Posted: Sat Dec 21, 2013 10:26 pm

by Andrew2

Nice work Phil.Do you do all your own welding,it's a nice job.

Cheers

Andrew

Re: Project - Nudo Nuovo

Posted: Sat Dec 21, 2013 11:16 pm

by Mc tool

My 1st chain slider , before I found a new one , was just a strip of plastic about 8mm thick, 25mm wide and long enough to do the job . I drilled 4 mm countersunk holes in it and drilled and tapped the swing arm , heated and bent the plastic and screwed it on . Worked a treat and if you didn't know you would never know

Re: Project - Nudo Nuovo

Posted: Sun Dec 22, 2013 5:11 am

by ducinthebay

I did not weld up the washer on the sprocket. I have seen a few of them that way. I assumed there was some company making them that way. It looks to be a robotic weld to me. Tough to make a good circular weld, and I don't weld. I have access to a lathe and mill, and know enough to poke holes in stuff, and make things fit. If it gets complicated, I talk to an engineer to CAD it up for me, then get the guys in the shop to run it on the CNC.

Cheers, Phil