Page 1 of 2

Understand the Weber (Weber settings+air/coils/fuel)

Posted: Thu Jun 25, 2009 1:34 pm

by romus

My findings in this thread and more is now found in the Weber 906 mod at

http://mysite.verizon.net/vze2hw9t/

SEE MY WORK IN POSTS BELOW

Re: Trying to understand the weber

Posted: Thu Jun 25, 2009 9:31 pm

by higgy

4. Issue is mostly lumpy running at low rpm, so ideas seem to be around making richer mix at low rpm, while not affecting nice running at high rpms. Parts of Weber considered:

The biggest issue I have is loading up on deceleration it gets worse as the weather warms up.

4.1 Warm air is better for burn mixture <don't know why>, so efforts in cold climates to draw in from motor heat helps.

Warm air helps with fuel atomization,generally cold air is better till the carb ices up

4.1 Holes at top of ET if smaller or soldered would enrich mixture at low rpm.

blocking the holes at the top of the et has just the opposite effect,leans or rather lessens the effect the et has on low rpm. Et's in general have more holes to increase the range of and promote the perculation of air and fuel in the reservoir of fuel around the et. While it is true adding air leans the mixture, the point is to lessen the effect the ET has over the idle jet circuit in effect you are increasing the flow rate at which the et has an effect, at the same time you are allowing the ac jet to have more control over the main jet

4.2 Auxiliary Venture if taller, affects sensitivity to pressure/burn mix at low air intake level by <don't know answer yet>, so if taller <don't know answer>.

Taller aux has 2 effects.( there is also short aux ) raises the top of the tube to help prevent sonic cross circuiting of the charge. not that important here .second is too increase the vacuum signal to the low speed circuit

The 4.5 tall aux has a larger opening to the reservoir around the et.provides a bigger signal but at a higher flow rate at the main venturi, has the added benefit of giving the idle circuit more control over low speed, it lessens the effect of the et on low speed, it also has the disadvantage of less control over the vacuum signal

4.3 Idle jet, if increased, enriches mixture at low rpms. Improves pressure compensation/burn mix when low air intake

the important thing to note here is you have to get the idle circuit right first and also it is the easiest jet to change on the weber..

You can't get the rest right if you don't get the idle jet correct

4.4 Pump jet, if increased enriches mixture on acceleration. Improves pressure compensation/burn mix when low air intake.

If you get the rest set it is less important, but it is the quick way to mask the rest

4.5 Coils replacements help with the spark timing <don't know why>.

Italian coils suck, nough said.anything else is better......aside from that you need consistant power at any coil,check those grounds and connecters first

just a few thoughts off the cuff after a long day..................if you would like to see what I am up to on the weber,send me a pm in the mean time check out ferarrichat.com weberology 501 and get yourself an innovate lm or lc to measure your ratio for yourself ttyl

Re: Trying to understand the weber

Posted: Fri Jun 26, 2009 9:50 pm

by JWilliam

I could write a book about how to get the best out of the Weber I've been refining the carburation for so long! About finished now though - super set up, very powerful... so much so that I nearly crashed it Wedneday night. That has to be the test don't you think?

* Coil replacement helps because the standard coil impedance is very low. There is a large demand for power because of this the Digiplex ignition unit overheats. Once this has happened it cannot be a suprise that the timing becomes inaccurate.

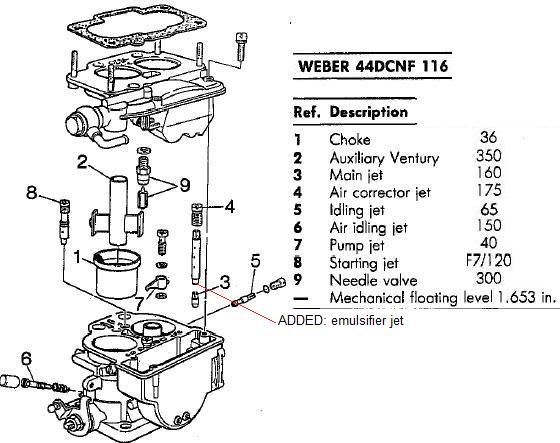

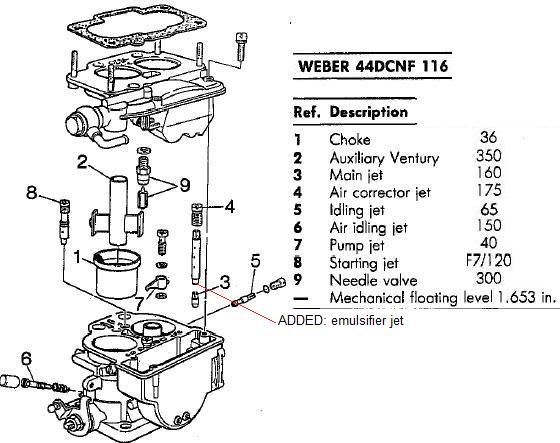

Picture of Weber 44DCNF 116

Posted: Sat Jun 27, 2009 2:08 pm

by romus

44 is throttle plate size, DC=Double thoat. The idle jet with F at front means it has ability for emulsifying fuel, jet numbers eg 160=flow rate same as if perfect 1.60mm hole.

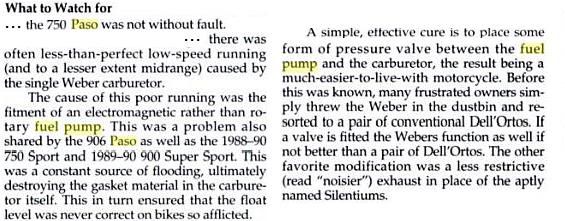

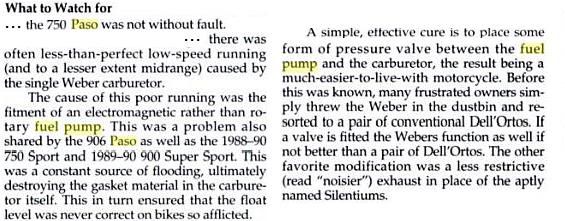

standard issue related to fuel pressure, as decribed magazin

Posted: Sat Jun 27, 2009 2:19 pm

by romus

Though I also read in On Ducati 1982-1991, Cycle World p64 "The same twin choke 44mm Weber carb is fitted to the 906 as on the 750 Paso, but the flat spot ... appears to have been eliminated."

The Fuel pump is the same part number for 750 and 906 Paso. I tested the fule pressure, due to different return line from 750 as ~1.8psi at the carbs, which is way under the recommended 3psi. If you put on a regulator put a Holley (designed for rreturn line position) to bring pressure up to 3psi.

Re: Trying to understand the weber

Posted: Sat Jun 27, 2009 3:15 pm

by romus

JWilliam wrote:I could write a book about how to get the best out of the Weber I've been refining the carburation for so long! About finished now though - super set up, very powerful... so much so that I nearly crashed it Wedneday night. That has to be the test don't you think?

* Coil replacement helps because the standard coil impedance is very low. There is a large demand for power because of this the Digiplex ignition unit overheats. Once this has happened it cannot be a suprise that the timing becomes inaccurate.

I'd love to know what changes you have made. I am working on tracking down and ordering jet options at the moment. also working on the fuel pressure regulator, K&N filter done, will do coils ASAP - then into the carb. This is new stuff for me but I love the bike, so I should let it be it's best.

Re: Trying to understand the weber

Posted: Sat Jun 27, 2009 8:46 pm

by JWilliam

romus wrote:

I'd love to know what changes you have made. I am working on tracking down and ordering jet options at the moment. also working on the fuel pressure regulator, K&N filter done, will do coils ASAP - then into the carb. This is new stuff for me but I love the bike, so I should let it be it's best.

I will post you a private message because I don't want Paso owners deciding to make any jetting changes based on someone elses set-up.

Re: Trying to understand the weber

Posted: Sat Jun 27, 2009 11:28 pm

by Grey paso

Hi guys Im not on the site much but saw you posting for tuning, Had my Paso Tuned (carboration in 1990 by and iolder duke enthusiast (Bike Factory Adealide pre 1985) and never had it touched since runs perfectly. His comment was regarding everyonr trying to make them work was that u need to be thinking like an Italian and how they meant the bikes to operate, run, behave. It has a factory pipe 2 into 1 and a proper after market air fillter. Regards Grey Paso

Re: Trying to understand the weber

Posted: Sun Jun 28, 2009 7:41 am

by ducapaso

Question #2: jetting;

Jetting a carburetteur is a sort of alchemy. The request of air is the most important thing in a carb, so is difficult to compare jettings in different engines. In example, lamborghini countach (same carb) has a very different air demand, but the same horns installed,so if you want to make any upgrade to paso, you have to be ready to try and start back from the first leg.

I put an 8mm plastic spacer between horns and carb and I felt a small but useful difference, this can be done just drilling properly a nylon plate, matching the upper seal.

Carb description & reference.

there's a part not mentioned, the emulsifier jet, I mean the one between #3 and #4: the later models (fiat engines until '98) had improved parts, with more drillings, able to mix better air and fuel, for a better response.

Re: Trying to understand the weber

Posted: Sun Jun 28, 2009 11:17 am

by higgy

IMNSHO, the single biggest problem with the weber DCNF is there is no provision for a power jet. A power jet allows for compensation of the mixture as the engine load increases or decreases, So in effect you have to set the jetting for an on or off style of riding. Lack of a power jet also means as the weather/elevation changes so do the jetting requirements. It also means you need a strong spark to minimize the the effects of a mixture that varies widely on part throttle deceleration or steady throttle conditions. JM2C

So in the end what has to happen is you set it up to idle properly and run under full throttle properly then get the et to run good on light throttle and compensate with the Accelerator pump to allow for good acceleration in the mid range

Re: Trying to understand the weber

Posted: Sun Jun 28, 2009 3:06 pm

by romus

ducapaso wrote:...

I put an 8mm plastic spacer between horns and carb and I felt a small but useful difference...emulsifier jet... the later models (fiat engines until '98) had improved parts, with more drillings, able to mix better air and fuel, for a better response.

There is a plastic spacer on my 906 - I hadn't thought about it - must be the work of a previous owner.

That is a great tip on an improved emulsifier jet. How would I get one - I mean which models of fiat, and/or how can I track down a part number?

Re: Trying to understand the weber

Posted: Sun Jun 28, 2009 4:32 pm

by ducapaso

That is a great tip on an improved emulsifier jet. How would I get one - I mean which models of fiat, and/or how can I track down a part number?

Fiat tipo/tempra 1400&1600 sohc

Fiat uno 1116&1301 & 1400 sohc

Lancia delta 1600 sohc

remember that F.I.R.E engines 1108cc and 1280cc use a single troath carb

Remember that dohc 1600 engine use a different carb

Re: Trying to understand the weber

Posted: Sun Jun 28, 2009 7:23 pm

by higgy

the 906 came with the plastic spacer as OEM.the idea being to lengthen the stack and minimize the rate at which velocity changes at the bussiness end of the carb.Does the same thing as putting a longer velocity stack on but then you cant do that on a paso due to tank/air box restrictions. IMNSHO it should have been a coolant block placed under the carb instead to regulate the temp at the carb throat would have gone a long way towards improving sales of a notable bike design. jm2c

My feedback on work for the Weber

Posted: Sat Jul 11, 2009 2:56 pm

by romus

My feedback on work for the Weber

[NOTE 8 Dec, 2009:

JETTING

I am using an LC-1 from innovate with a gauge to read the exact air fuel mix (AFM). I have this connected to the exhaust of the front cylinder, but can swap to the exhaust for the rear when i want. So far I have made carb changes and test rode maybe 20 times and with numerous more garage tests for idle setup affects.

With my setup and the factory F27 ET the air fuel mixture variation goes from a little rich to a little lean 12s - 13.5 or 12.5 -14. This is possible with the F27 and with enriched jetting if the idle is adjusted.

That range though is a little too much, so I started work testing other ETs and filling holes and drilling them for custom F27. In the process, I also arrived at 12.8 - 13.2 AFM as a really nice riding feel, where the bike becomes light yet powerful- so that is where my goal is.

I think I have come up with a custom ET that evens out the AFM mix across all speeds/rpm with a smaller range, but need to do more testing to be sure (I have tested this at two different times for low speed testing and high speed. In theory, I have it dialed in nicely, but need a full ride at all speeds to be absolutely confident). I have an overheating problem I am working on fixing before I can do that. (9 Dec, 2009)

One I dial in the front cylinder, I will also test the rear cylinder to work out how the jetting should be adjusted. I think the bend in the manifold to the rear cylinder causes a drop off of fuel in the mix as it travels to the combustion chamber. It needs richer jetting, whatever the explanation. It could even be the ET wave (~) may be different for the rear than the front cylinder.

Then I will come back to the airbox. I am using a closed one at the moment. The airbox affects the AFM, so I want to test the effect of opening up an airbox with better jetting and measure the AFM effect. Well, I have done that at low speeds and surprisingly found it goes richer at low speeds when you semi-open up the lid by .5 AFM. At speed- I have not tested yet. END NOTE 9 Dec, 2009]

I have had help from

JWilliam and Higgy whose knowledge far exceeds my own and to all the posters on the subject on this forum – just great. There is also a forum http://www.ferrarichat.com/forum/ where is there is detail on Weber tuning by mostly Ferrari owners.

My preliminaries for intakes and exhaust are:

b.1 fuel pressure at carb ~3psi set by adding a Holley 12-804.

b.2 Termignoni exhaust

b.3 closed air box with one air intake pipe.

b.4 itg filter, also similar affect with K&N filter

b.5 engine venting filter, which goes on airbox outlet by battery, and therefore plugged venting tube to carb airbox. This meant engine fumes are vented to the atmosphere and not back into carb airbox affecting the AFM reading.

b.6 Electric mod for good voltage to coils, to makes sparks strong (see mod on this site)

b.7 coils replaced, to makes sparks strong (see mod on this site)

My carb settings based on air/fuel mixture guage readings are:

I am at sea level and warm - hot air temperatures.

- float level 42 (factory setting)

- Venturi 36 (factory)

- Main Jet: testing

- AC jet: testing

- Idle jet: 65 (Factory)

- ET custom F27

- Accelerator jet: 35 (Factory was 40)

- Auxiliary venturi: 4.5 (Factory was 3.5)

Recommendations: It seems, Engines are all a little different and the setting will need to vary according to weather, altitude and your riding preference. The investment of an LM-2 from Innovate would be well worth it - then test stepping the Main and AC jets up and down from a proven cluster. Your own weather, altitude, fuel pressure, air intake, exhaust output will affect adjustments.

Fuel pressure and float settings are sensitive ie they will affect the tuning if adjusted slightly, so get this right first as well as settling on your air intake and exhaust system. You might need to step one jet size up or down from my preferred cluster.

Here are some things I learned:

1. The float level matters, start at 42 mm factory setting. If in the end you want everything a little bit richer increase the setting to 40mm.

2. You might have an open airbox, but maybe a better way is to keep it closed factory with some intake pipes gently feeding air in when you have a little speed.

3. When the jetting is not right you get uneven fluctuations and get confused. It is like whistling - if it is not tuned right it just doesn't work. getting it right is about getting the cluster right (air intake, fuel pressure, exhaust, float level, Idle jet, accelerator jet, venturi, aux venturi, main, AC, idle jet, ET, manometer venturi balancing, idle screws set).

3. The factory venturi size is big for performance at speed, which means it needs care to tune the low end - but if you can do that you get best of both worlds. Changing the aux venturi for 4.5 is a clear improvement.

4. To take off the top of the carb jam a socket onto an allen key and undo nuts by putting allen key though holes in top of air box. Also because the nuts are fiddly lay a rag over the motor in case you drop a nut.

5. Want to put the AFM richer a bit - go up one main jet size (which is 5), for the same result it takes ~ 3 steps (which is 15) down in size of the AC jet.

6. petrol has changed. There is a need for a new cluster to tune the bike right.

7. Using an Air fuel meter like the LC-1 or LM-2 from innovate gives you the confidence to test effects of tunign variations.

See the work, below:

Fuel: Premium unleaded

Fuel pressure

I tested adding a Fuel Pressure regulator, learning that for a 906 it is not needed (the 906 tank return line is different from the 750, so pressure to carbs is different). I found pressure at carb at 1.5 – 1.8 psi, which I understand is acceptable. [Edit Aug 09: But I was concerned the low pressure may underdeliver at high speed when the demand is gretaet. I went to a holley for 3psi and reduced pulsing. Pulsing can also affect the float level, apparently.

Air intake system

I added an itg filter (also had K&N Filter DU-0900), which on its own made a big power increase with open air box. After that I taped up the holes in the lid and attaching some flexi piping (TPR 40mm heat resistant flexible piping ) to the left hole, twisted forward. I now have two rubber pipes out and facing forward from the holes in the bottom of the airbox. One is longer going forward to behind the radiator. This encourages air intake flow when driving. I learned that an open air box gives acceleration power, but at high speed the carb can do with even more air, so maybe closed airbox lid and thinner racing filter with closed lid better for high speeds. I also found the closed airbox gives a leaner AFM setting on idle, by half a point, than an open airbox, So closing the airbox does not choke the air off.

Electrics

For a noticeable improvement to spark plug firing (now hardly any or no missing when first starts) I added a relay to get a more direct 12 volt feed to the Coils. http://www.geocities.com/davidhooau/pas ... _mods.html the one refereed to as the "Main Feed relay". I followed the instructions, except I made crimp connections rather than soldering. I rode the bike with the relay before I changed the coils and already there was a very noticeable improvement.

I then changed the coils for Japanese ones with 3 ohms resistance (my Honda 250 coil choice from the wreckers, was a bit tricky because the leads were different and I had to change the lead fittings (guy at wreckers checked 3 ohms with multimeter). I found a bike frame engineer to make me up two brackets for the coils, so they attached nicely to the same places on the frame. You can see one of them here:

Notice the mini fuel tank - enables some checking with the motor on and then to make adjustments without taking the big tank on and off.

I am also going to try some Iridium spark plugs.

Weber 44 DCNF 119: To the heart of the matter  .

.

I ordered from http://www.piercemanifolds.com/ Tall aux venturis 4.5 (up from 3.5), some main jets, AC jets and idle jets to start testing, using the LC-1 to measure the Fuel Air Mix (AFM).

I ordered a maintenance kit (Weber 40-42-44 DCNF Carburettor Kit) in my case from MLP Carburettors - http://stores.shop.ebay.com.au/MLP-Carb ... QQ_armrsZ1

To change aux vet: Took off air box, covered engine vent intake hole hole inside air box with tape and stuffed rag in venturis to avoid dropping nuts down them.Also put rag under airbox incase I dropped nuts that way. Undid bolts holding venturi on (top of air box has plug holes, so removed and used socket with allen key jammed in to undo bolts). Lifted venturi bits and air box off. Took off fuel hose. Undid 4 bolts at top of carb, to lift off top of carb, being careful not to damage float. Undid the 4 bigger bolts at base of carb, slipped accelerator cable off the ball joint. Now can handle carb on my knee on chair beside bike (still is attached by the choke cable). Used handy wooden bits as dowel to tap out aux venturis and tapped new ones into place.

NOTE: (As per comments on this thread by "Higgy" and Nicola aka "Dukapaso"), I made a water vacuum tester to check both carbs are timed together.

I ordered an LC-1 to measure air fuel mixture (rich/leanness) at different speeds/rpm so I can test the jetting accurately.

Re: Trying to understand the weber

Posted: Sat Jul 11, 2009 6:28 pm

by higgy

Innovate also makes a device called an LC-1 It is a little cheaper than the LM-1 But does not give you the ability to record and download to your PC. You can hook it to a pc which would be difficult on a PASO, or a digital gauge which by the way fits in the hole for your most likely not working clock and get live readings of your mixture.Don't forget e-bay.I have seen on occasion a complete LM-1 with an rpm converter go for under 200 here in the US. Not long a go one went for 135 complete except for the power cord which really would be no big deal to fabricate.

To sync your carbs is easy,all you need is about 6 feet of clear 6mm or 1/4inch tubing some colored water and a board( or plastic or cardboard) to mount it on. Seems to me there is an article in the 750 FAQ on making your own U-tube manometer. no need to waste your bucks on a mercury manometer when water will do the trick only need a few tablespoons of water so no need to worry about injesting it in your precious engine if you fumble around and only get one side hooked up and suck up the water. You could also get at your local tropical fish store some very cheap valves to allow a more casual hook up.The idea is to balance the two columns of water to the same level at idle and 2500rpm by adjusting just one of the two idle set screws on the Weber.Does not matter which screw could be either.Generally you adjust the screw which lowers the high side water column but this is not always the case. The important thing to remember is adjust only one screw so that the other stays closed completely to get the columns of water to the same height in the u-tube

Though I also read in On Ducati 1982-1991, Cycle World p64 "The same twin choke 44mm Weber carb is fitted to the 906 as on the 750 Paso, but the flat spot ... appears to have been eliminated."

Though I also read in On Ducati 1982-1991, Cycle World p64 "The same twin choke 44mm Weber carb is fitted to the 906 as on the 750 Paso, but the flat spot ... appears to have been eliminated."