Page 2 of 2

Re: Weberology 101 Final Exam

Posted: Tue Feb 16, 2010 9:25 pm

by JWilliam

I am glad you are stating that it is not an imperative that owners modify their machines to these specifications. The Weber carb standard setting gets it through EC noise and emissions tests, although not perfect it runs acceptably. Tuning the engine makes the Weber very sensitive to air temperature (air density) for one. Varying fuel pressure is a very effective method of compensating for air density (once you've got the jets correct), generally I use 3psi for temperatures below 15C lowering to 2psi above 30C. The power difference between cold and hot weather is startling, making me wonder if those injected fellows have got it quite all right. Also I must question your suggestion of increasing the air jet when increasing the main jet. Using the (πr2) formula against the chart shows that the setting 165/145 vs 190/220 gives a fuel mix almost half the final fuel volume using the larger jets! ie 165/145 is the richer setting. I tried the larger air corrector method when increasing the main jet years ago and it just would not run.

The original airbox needs the inlet snorkels or it will get air starvation above 120mph - its all very well testing these changes in a workshop when you need a wind tunnel but Ducati know their stuff and if you only ever learn one thing when trying to improve on a standard motorcycle its how good 'they' are at building them as competent all rounders.

Of course it will make good reading to hear about any mods to owner machines but I for one will now keep such alterations to myself, principally because my changes are so different to yours and it would be confusing if not misleading to have conflicting settings advertised by forum members I think.

Re: Weberology 101 Final Exam

Posted: Wed Feb 17, 2010 12:31 am

by romus

JWilliam wrote:...Tuning the engine makes the Weber very sensitive to air temperature (air density) for one. Varying fuel pressure is a very effective method of compensating for air density (once you've got the jets correct), generally I use 3psi for temperatures below 15C lowering to 2psi above 30C. The power difference between cold and hot weather is startling, making me wonder if those injected fellows have got it quite all right. ...

It is a good point. This is where the Weber lacks a "power jet", isn't it? So, there is no automatic adjustment for air density compensation on the Weber, whether by temperature or height above sea level. So changing the jetting to compensate for that is one way and changing the fuel pressure is another. I noticed a change when riding up 1,000 feet the other day - If I had a knob on my dash board attached to my Holley fuel regulator, I could have turned it slightly to reduce pressure/lean it for the height compensation -hmm.

JWilliam wrote: Also I must question your suggestion of increasing the air jet when increasing the main jet. Using the (πr2) formula against the chart shows that the setting 165/145 vs 190/220 gives a fuel mix almost half the final fuel volume using the larger jets! ie 165/145 is the richer setting....

165/145 and 190/220 are approximately the same air fuel ratio - it is just the volume that is changing. This idea of going up a step (1 main + 3 ACs) is suggested only later in the tuning steps (after one already has the jetting pretty well right) and only if there is some slight bogging still at the very light acceleration point before the fuel pump kicks in. So, it just has the effect of getting fuel flowing just that little earlier to get that lean spot. It is not meant as a tuning idea other than that To increase volume from 165/145 to 190/220 would be far too much a jump.

It is one method, along with a very slight increase in float level to resolve the Weber lean spot on slight acceleration (before the fuel pump kicks in). The taller aux venturi also must help.

Actually, we have now tested the Grose jet, and it is an even better alternative method to get that lean spot - also providing better response.

Re: Weberology 101 Final Exam

Posted: Wed Feb 17, 2010 1:29 am

by romus

JWilliam wrote:... my changes are so different to yours and it would be confusing if not misleading to have conflicting settings advertised by forum members I think..

By settings I guess you mean jetting and turns of idle screws etc and fuel pressure.

What we have done is shown our setup info along with the jetting because yes, it is so interrelated. By using Innovate AFR sensors in line with the target AFR we show some proof of the significance of fuel pressure, airbox lid and even cam timing.

Providing our settings (as AFR tested) for those who make some or all of the mods (and we provide info on the AFR difference of various factors) provides a reference/starting point along with the reference of ones own original settings, to tune in the right direction. Otherwise, it is is easy to get lost in the tuning process.

Re: Weberology 101 Final Exam

Posted: Wed Feb 17, 2010 2:20 am

by higgy

making me wonder if those injected fellows have got it quite all right.

Depends on the system. Computerized feedback systems rule. early systems like found on the 907 needed a lot of tweaking.

It is all about what you can measure and accurately respond to in a repeatable fashion. comes down to the quality of your sensors and the response time of your software

But none of that matters much on a carb system, does it?

Re: Weberology 101 Final Exam

Posted: Wed Feb 17, 2010 10:04 am

by paso750

the correct name is I guess a diaphragm fuelpump.

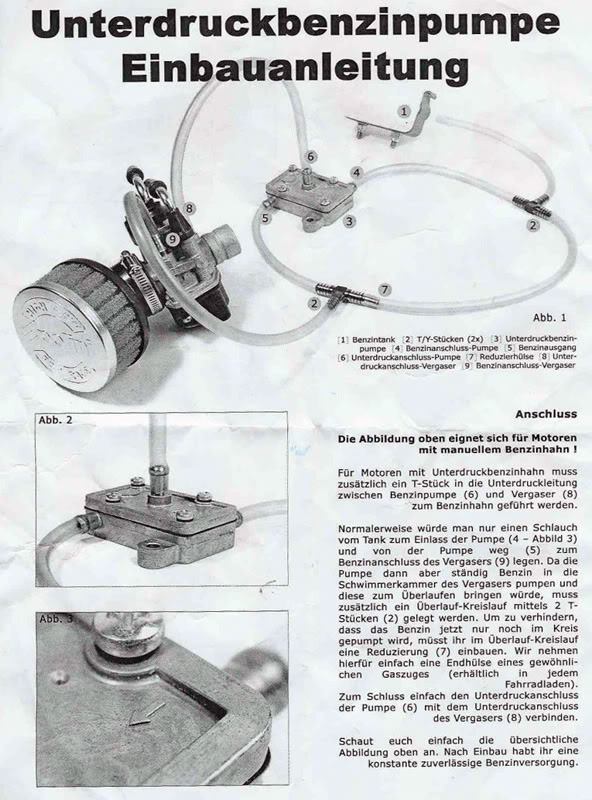

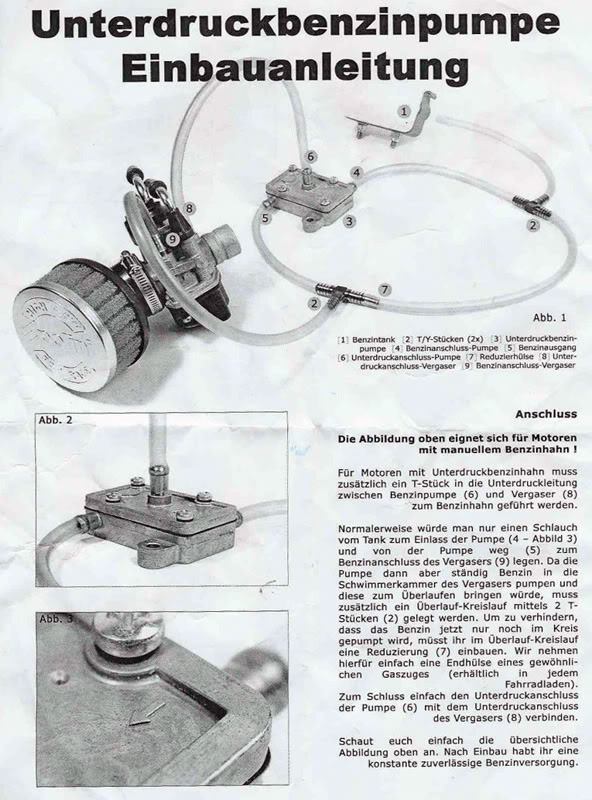

basic setup (7 is a reducing bush, 2 is not required if the tank has a return line)

I found the webpage (

http://www.8ung.at/manxman/ ). The guy used one from an old Yamaha TDM850 (Duc Monster also use them). He used one of the connections for the sync tester on the side of the inlet manifold and put in a screwing nipple he connected the fuel pump to. (actually he used a M4 thread rod, drilled it though and glued a nut onto it). He says that the pulsatory suction process moves the diaphragm and delivers the fuel evenly independend of rpm which corresponds to what higgy had said. So I guess I was wrong again. Still worth a try though.

Re: Weberology 101 Final Exam

Posted: Wed Feb 17, 2010 12:31 pm

by Tamburinifan

The power difference between cold and hot weather is startling, making me wonder if those injected fellows have got it quite all right.

We have Air temp compensation in software.

At +10 C you get like 5-10% more fuel than at +30 C, generally speaking.

In starting procedure, it could vary 30-50% between 10 & 30C.

Re: Weberology 101 Final Exam

Posted: Wed Feb 17, 2010 7:24 pm

by Mc tool

quote Higgy

At the moment I have a 195 Cummins engine going for a baseline test.

Its a diesel but just as an example........

Cant see the point in that Higgy, It doesnt even use a webber and you'll never get it in a paso!

Re: Weberology 101 Final Exam

Posted: Wed Feb 17, 2010 11:05 pm

by higgy

Re: Weberology 101 Final Exam

Posted: Thu Feb 18, 2010 7:35 am

by Mc tool

I think that Jesse James pillock put one in a trike , or more correctly destroyed a perfectly good truck to the point that he had to call it a trike

Re: Weberology 101 Final Exam

Posted: Thu Feb 18, 2010 5:19 pm

by JWilliam

Well I run my engine at a lower temperature, certainly have different jet setings and can manually alter fuel pressure on the fly for a start. So as I said to Higgy via a pm the document is a super production but Paso owners should work through this and make their minds up rather than another owner offer conflicting setings and create possible confusion. But you have made this a public document and I am duty bound to state that under some subjects I disagree.

romus wrote:JWilliam wrote:... my changes are so different to yours and it would be confusing if not misleading to have conflicting settings advertised by forum members I think..

By settings I guess you mean jetting and turns of idle screws etc and fuel pressure.

What we have done is shown our setup info along with the jetting because yes, it is so interrelated. By using Innovate AFR sensors in line with the target AFR we show some proof of the significance of fule pressure, airbox lid and even cam timing.