higgy wrote:I truly believe the kit proposed works ( I find it a little bit pricey, but i guess you pay for the convenience of having a "kit" taylor made) , although I am preatty sure that just by disassembling, cleaning, lubricating and reassembling the old wiring it would make a noticeable difference.

Actually, 75 dollars is not "that far off of the price" of all the components these days. But the real expense is the crimpers.

If you have the proper crimpers, I agree 75 bucks is high.

Say Folks, since I am just now creating some documentation for my site addressing the above topics I thought I would chime in here.

The first point is that with fixed value DC electrical circuits there is a "formula" which basically states how the circuit should work.

1 - You have the electrical supply of 12.85 volts (the battery)

2 - You have the electrical consumer which wants 700 watts (the Denso .7 kilowatt starter motor)

3 - You have the desired end result (the starter turns over the engine and the bike starts)

The above formula says to make the circuit happy we have to get right about 54 amperes to the starter.

Now if you have the very smallest amount of resistance possible in the connecting wire and terminals, what happens?

Well, with the HICAP kit in place, the engine starts up in somewhere between .3 to 1.5 seconds on virtually every bike out there. Even big 1198s with higher than stock compression (like 12 to 1 etc.) start in about 1.5 seconds (down from 4-7+ seconds).

And since the circuit is a fixed circuit (we can't change how much energy the starter asks for etc.) the above scenario defines the true (originally engineered) performance of the circuit. ( I use the term energy and not current because as the voltage goes down the amount of current required goes up, at 12.2 volts the current has to be 57.37 but if you did have 12.85 then you only need 54.47, both equal the same amount of energy and will get the same job done). The 12.85 volts is open circuit meaning with no real load. In my videos you will see the actual working voltage drop down into 12.2-12.4 as soon as the key is turned on and the battery has to start doing some work.

So, if we have the 12.85 volts (modern AGM batteries when measured "open circuit" are now all at about 12.85 when fully charged) and the starter motor is not hosed, than anything longer than about 1 second (on average) is excess wear on some pretty expensive parts of the motorcycle. I had thought that starters were about $300 but was just told by a guy who had to get a new one that they are actually $600 - he was pretty happy that it tanked within his 2 year warranty. That's right, his 2 year old Multi Strada ate a battery and a starter within 2 years due to his having to crank the starter so long to get the bike to fire up.

So the point of the HICAP kits and why they are engineered the way they are and with the particular raw components is to get the resistance to be the lowest possible and to keep it there for as long as possible.

If you're wondering where the energy went if it wasn't getting to the starter - it was being turned into heat at each of the terminations and along the wire length. If your bike is slow to start, you can feel the heat in the leads as it cranks around. The terminals will actually get hot.

And Higgy is right, you just cannot get the very high pressure needed to really compressed the metals together using anything other than a professional level crimping tool. Trying to crush things in your vice does not get you there.

As for the pricing on the kits, it is actually based on a normal business formula for hard goods. It takes into account the cost of materials, cost of paid labor to make, package etc. I have looked at every possible way to get the price lower and the only way to do it is to really cheap out on the parts (source crap from China etc.) and not do the little hidden things that I do to make the circuit last so long. And that's not the way I go, it's do it right or I won't do it.

The list price on the (Paso) HICAP is $90 for a dealer to sell at and I sell them direct to rider/mechanics at $75 and pay the shipping. The kits are priced to be sold through the dealer network to allow them to help the 50%+ of the Ducati owners who do not do their own work. This way the dealer can make some money and feed his kids and (hopefully) stay in the business so the rider can have a reliable bike. (My county has lost 4 motorcycle dealerships in the last 2 years, we're down to 1 in the whole county).

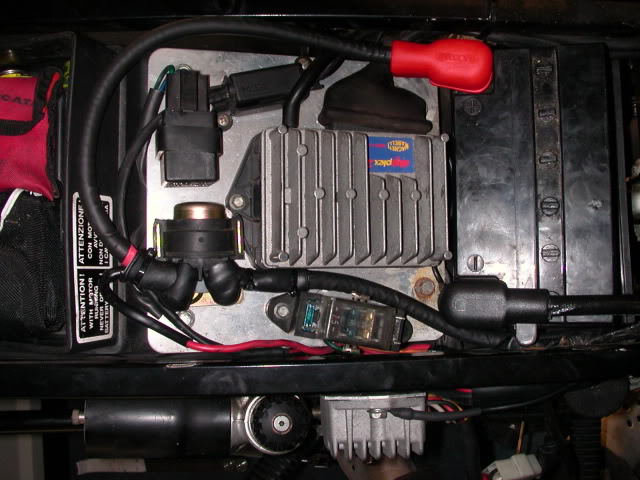

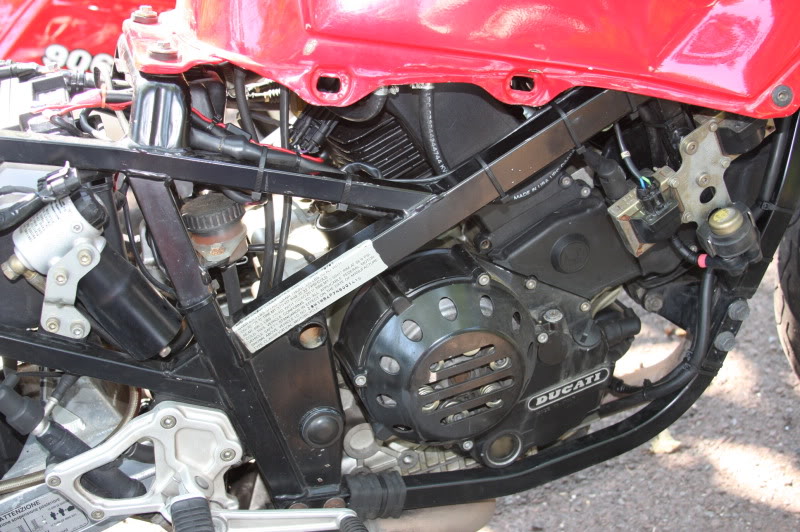

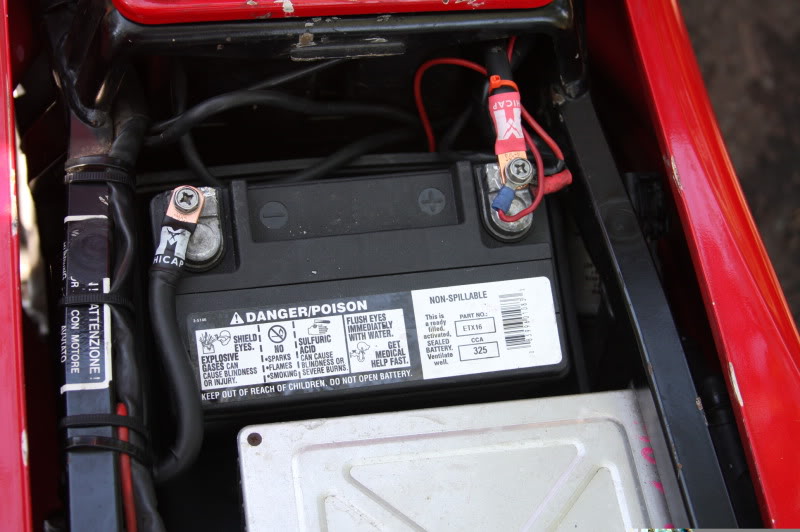

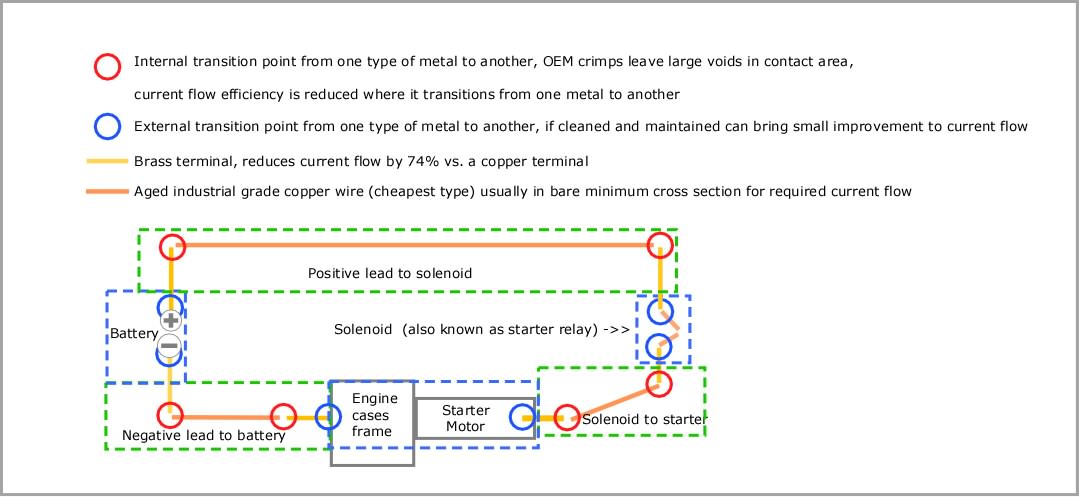

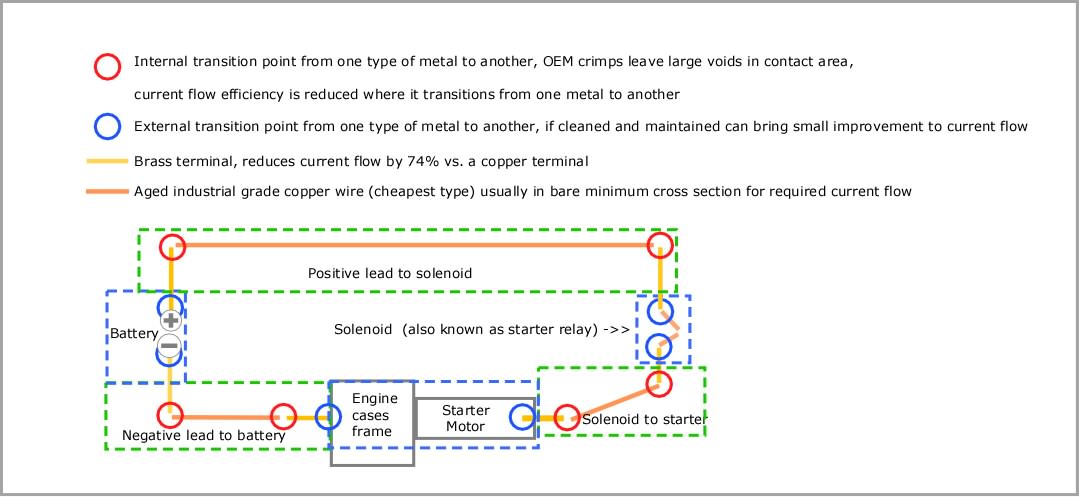

To help folks understand the finer points I have a couple of images below (the graphic is a work in progress and still kinda rough).

The parts of the starting circuit in the blue boxes are fixed and my kit cannot improve them. The parts in the green boxes are what is upgraded in a HICAP kit. As I show, although you can go ahead and clean all the connections there is a high portion of the circuit that you cannot clean and the cleaning effort will be pretty close to the same amount of work as installing the HICAP. And then there is the fact that the cleaning will just not get you down into the 1 second range that will maximize the life of your starting system.

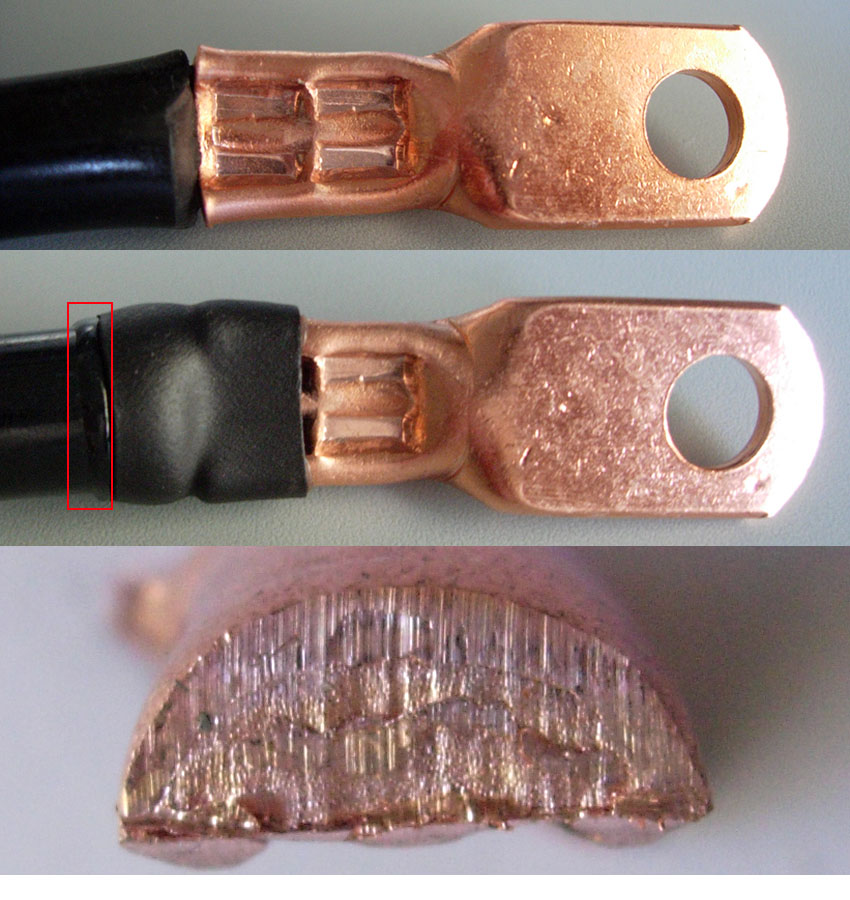

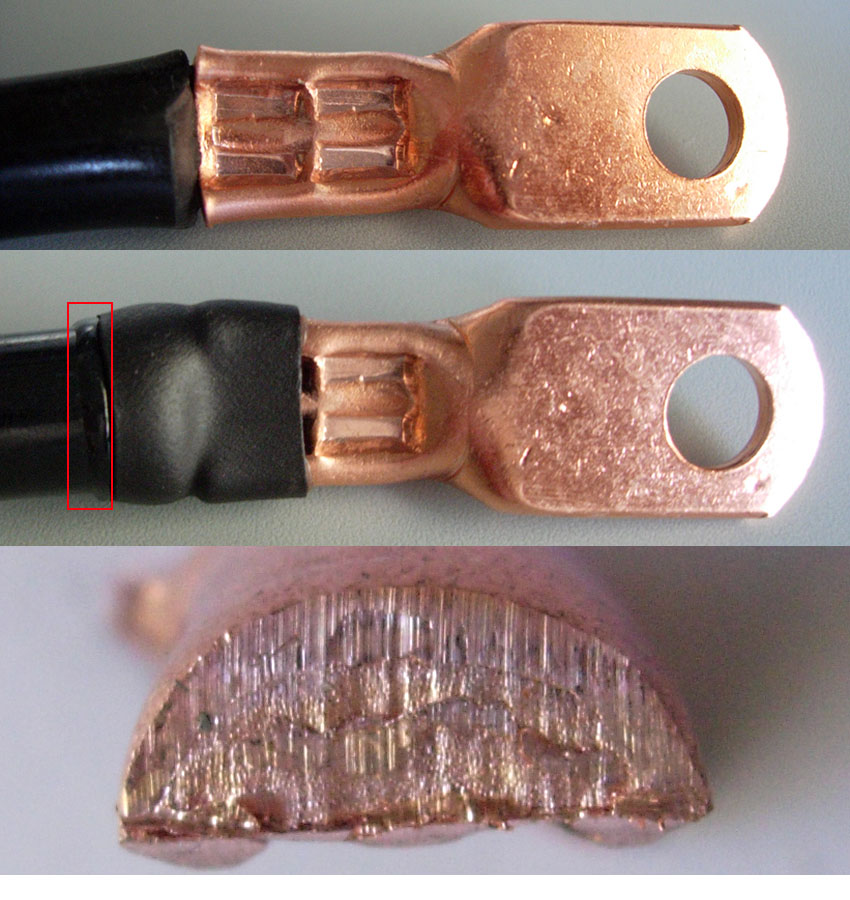

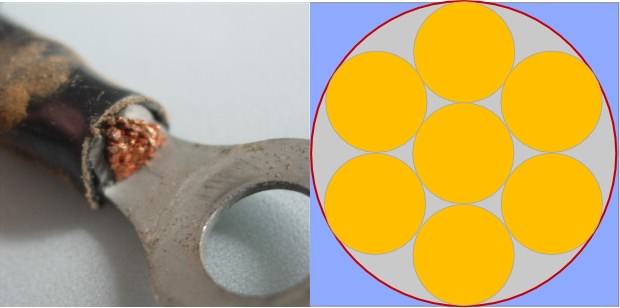

The next graphic shows the hidden steps taken to maximize the performance life of the HICAP product. The electrical industry standard for crimping a 4 GA cable to a terminal is 1 crimp using a high pressure tool like I do. But I do 2 crimps so that I completely crush the copper together to evaculate all of the air in the terminal. What I have left is as close to a solid copper termination as possible. I then use a double wall heat shrink that is lined with a hot melt adhesive. As it shrinks it conforms to the terminal/insulation juncture. The hot melt seals the juncture against the environment and also reinforces the terminal edge and the outer shrink that is the last layer of the lead (also increases the heat resistance to about 220+F).

The next image is of a terminal that I cut in half, as you can see the 1000 strands of copper are crushed together with virtually no gaps of any type. Over time the copper with fuse together and blur the point where there was wire and there was solid terminal.

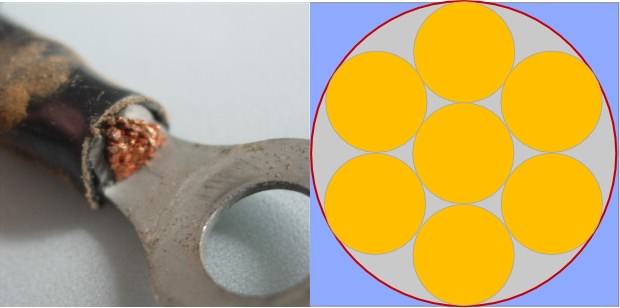

Finally the last images illustrate the problem of the OEM transitions from their low strand count - large gauge wire strands and the terminal surface and how it leaves gaps in the contact area. Copper is a fairly soft metal but it does get stiff if it is thick. The 37 GA strands in the HICAP are extremely thin and bend/crush together when crimped causing the gaps between the individual strands to be compressed or eliminated. Not so with the thicker strands of conventional industrial grade wire. The 37 GA designation of the HICAP individual wire strands means the copper went through reducing dies 37 times. Conventional wire of the same gauge will have a strand count that is much lower although the cross section would be the same. Conventional wire costs less in part because they don't run it through reducing dies so many times (which costs money) and so the strands are thicker. But then the OEM wire is really in the 6 gauge range, the HICAP uses 4 gauge.

As I mentioned in a prior post I welcome any and all questions or concerns about these types of things because they allow me to work through educating folks who come to my site.

I want to thank Higgy for the feedback he gave me in emails and for sending me the photos of his install and for posting them here in the forum.

Thanks,

M./