Page 4 of 4

Posted: Thu Apr 26, 2007 5:01 pm

by paso750

Since the Version B piston looks bigger, I wonder if they were trying to improve the clutch feel?

In fact rougly measured the cylinder of my old cover has a diameter of 26mm and the new cover measures 31mm.

Posted: Mon Jun 04, 2007 6:23 pm

by PascoPaso

I ordered the piston 748-996b-st4-900m/00 part number 19590023b. 25mm, one v-seal hydraulic type on the piston on the lower outer end, plus an inner seal. For a rod I suppose? That had to be pried out for the new bearing. The new spring was the wrong depth, so I used the old spring, until I can find a new one or modify this one. For the button I used an 8mm 316 marine stainless 8MM allen head. I cut and ground it to the size stated previously. Then I drilled a small hole in the center so there is an insert for graphite from a pencil, for lubrication between the two mated metal surfaces.

Here comes the interesting part. Then I tried to get the old button out of the piston that I had removed from the Paso. It did not look like the one that was on ebay or any of the links. Then I broke two new drill bits trying to bore a hole through the spring side!! I dulled a saw blade. After I removed the seal and cleaned the whole thing, it turns out there is no button at all, per se! It has an O-ring for a hydraulic seal, "a hardened steel button&inner race", eleven 4mm ball bearings, a smaller needle bearing in the bottom of the "cupped piston", a c-clip to hold the button-inner race in place, and a rubber seal around the button&inner race on the outside facing edge. The only markings anywhere are Germany and some tiny numbers on the needle bearing.

Should I use the new one or the old one? Does anyone else use this type of piston in their bike. This is the source of my clutch noise, but not the bearing. More or less the two metal faces rubbing together? Graphite or teflon? I ordered seals for the piston end. And I want to replace the o-ring with the newer seal, maybe the 900SS one will work. The new ball bearings were purchased from the local bicycle dealer.

Posted: Mon Jun 04, 2007 7:17 pm

by ducinthebay

If your has an O-ring on the piston, then you have the more common Type A piston, which as you described, has a whole bunch of stuff in it and is not easily replicated.

The Type B has the o-ring in the cover and is much simpler to replicate, except the groove in the cover.

They are different diameters also.

cheers,

Posted: Mon Jun 04, 2007 7:51 pm

by PascoPaso

Thanks, yes it is the "A" piston, similar to the part that I ordered. So, I built a second button out of marine brass, 8mm or 5/16 inch bolt, center drilled for graphite "pencil lead". This is my "spare piston" for now.

I am using the original piston that is pictured, for now? But it has the new hydraulic seal from the 900SS piston, packed with new high temp grease, and a very small amount of teflon paste on the mated metal surface. Now the noise is gone! No leaks! Smoother pull on the clutch lever!

Posted: Wed Jul 11, 2007 2:00 pm

by izaakb

Hi folks

I stumbled onto this thread and thought I would offer my experiences.

I have 5 different Ducati/Cagiva bikes which have the right side clutch slave. I tried to rebuild the clutch slave on an Alazzurra and picked up a cover from a 750 Paso.

Found out the pistons were different sizes. That intrigued me, so I started collecting on the right-side clutch setups.

I found there were at least 4 different types of pistons:

Size (usually 28 vs 25mm piston, and an oddball 31mm on later TT2)

Oring vs non oring (some have the oring in the bore, not the piston)

I've also sourced a machine shop who can make pistons, if anyone is interested. I was interested in sleeving my 28mm cover down to a smaller piston so I could use a different master. The Alazzurras have the oddball 15mm Brembo clutch master, which is very very very rare to find.

FYI the correct way to remove the button is to use two thin pieces of metal (such as a hair clip) and insert it under the edges and rotate. It takes some practice, but I can do i right away. You just push in as you are turning. The grease on the bearing sometimes cakes and makes it a bit sticky.

Re: Clutch Piston

Posted: Sun Feb 15, 2009 3:21 am

by Desmo_Demon

Oh, the "search" function is a wonderful thing!!!

I finally got around to taking my clutch slave piston out because the metal shield on the one side had come off. The more I looked at all the components, I knew I was in trouble. After two hours of messing with it, I finally have everything apart. The brass button had the head worn off to where the outer race of the bearing was hitting the clutch pressure plate and a slight champhor was worn onto the outer race. To make matters worse, I could not remove the shaft of the button from the inner race of the bearing, and the bearing did not want to come out of the piston. I had *fun*...

I removed the metal shield, used a small punch to knock through the bearing ball cage, and removed the outer cage. I then used a Dremel and notched the inner and outer races and removed three or four of the ball bearings so I could remove the inner race. Now, I had the outer race still stuck in the piston. To make a long story short, I spent about an hour, slowly cutting through the outer race until I was able to knock the outer race out of the piston.

Now, I need to buy a new bearing and have a friend machine a couple of the brass buttons for me. I may replace the o-ring while I'm at it.....by the way, I have the "Type A" piston where the piston is notched for an o-ring.

I was dreading working on this slave piston, but it was my excuse to not work on the valves of my 748.

Re: Clutch Piston

Posted: Sun Feb 15, 2009 2:34 pm

by jcslocum

Terry,

A bronze product will be better for the button than brass. Maybe he has some of the self lubricating types...

Re: Clutch Piston

Posted: Sun Feb 15, 2009 4:29 pm

by Desmo_Demon

jcslocum wrote:A bronze product will be better for the button than brass. Maybe he has some of the self lubricating types...

Yes, you are correct. I meant to say bronze. My buddy made a bronze bushing with o-ring grooves for mounting my wife's shifter to her R1. I believe he used a self-lubricating type of bronze, if I remember correctly.

Interestingly, I cannot find an automotive application for the 608-ZZ bearings, but apparently, those bearings are heavily used on skateboards.

Re: Clutch Piston

Posted: Tue Feb 17, 2009 1:32 pm

by Desmo_Demon

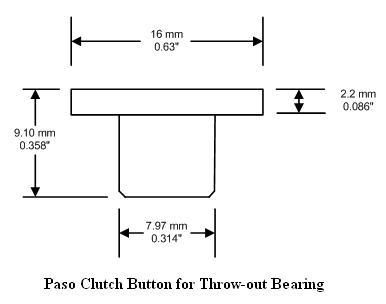

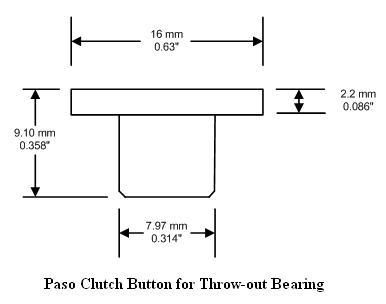

I used Gerhard's diagram and made another one. I'm planning on stopping by a machinist buddy's place today and see if he can make me a couple of these. I'm picking up the replacement throw-out bearing this afternoon, also....

I'm hoping to have the Paso back together by this weekend so I can out a couple hundred miles on it.

Re: Clutch Piston

Posted: Wed Feb 18, 2009 11:51 pm

by Gwenadu

1st time I try to put a pic...

Alain.

I fixed the pic post code. There is a "Hot To" in the FAQ section.....

Re: Clutch Piston

Posted: Thu Feb 19, 2009 1:42 am

by higgy

almost post your pic like this

Hit the image button Img above your edit post window which will put 2 [/img]into your post then insert the following between the 2[/img]

http://s587.photobucket.com/albums/ss31 ... 120247.jpg

edit: correct it`s

Re: Clutch Piston

Posted: Wed Mar 04, 2009 4:22 pm

by Desmo_Demon

I got the bronze button machined by my buddy and have the Paso back together and the clutch bled. If all goes well, I may take it for a spin around the block this afternoon, and then I plan on riding it a couple hundred miles this weekend. It's supposed to be bright, sunny, and about 70-degrees (F) this weekend.