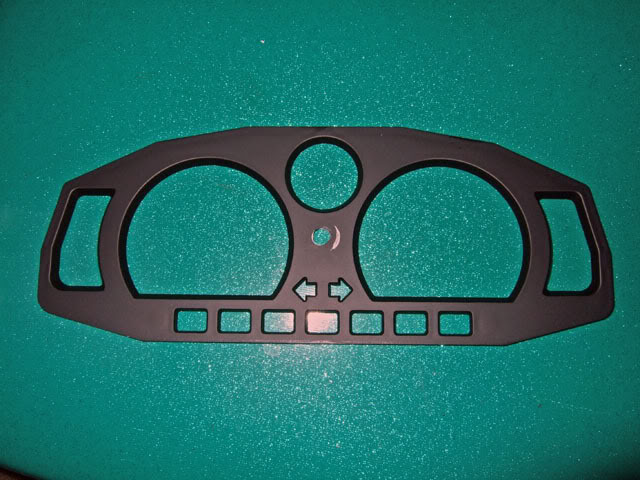

There`s no such thing you can buy for your Paso, you`ll have to make it. For the Monster I`m not sure. There`s a kit for the Superlight and one for the 888. The one of the SL needs minor mods to be fitted on an 888 (it needs to be narrowed by 4,6mm). No idea if one of those would fit on a Monster.I've been looking for the pieces & parts to put that on both my Paso and the Monster.

PS: I normally wouldn`t know that but I had got a set of an SL at first and then sold it to a friend with an 888

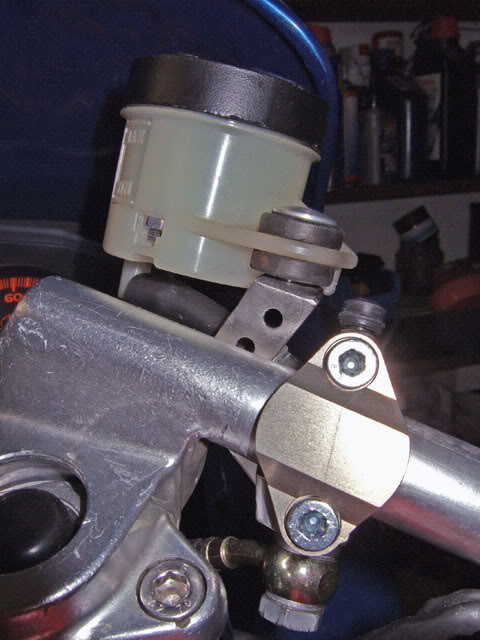

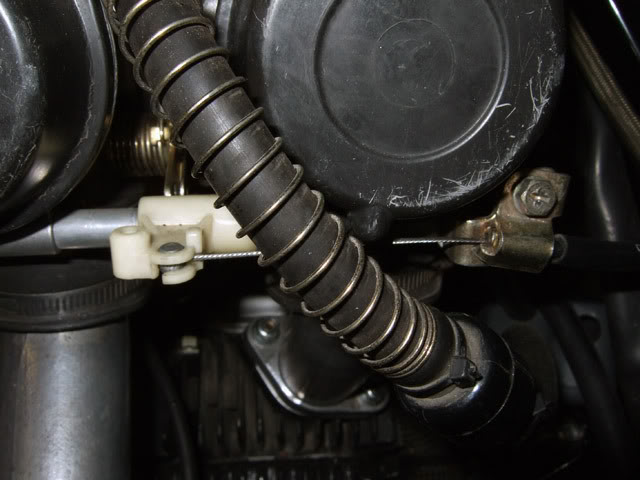

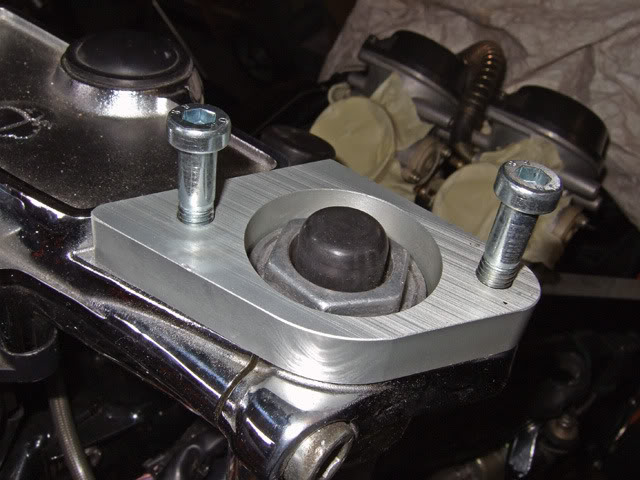

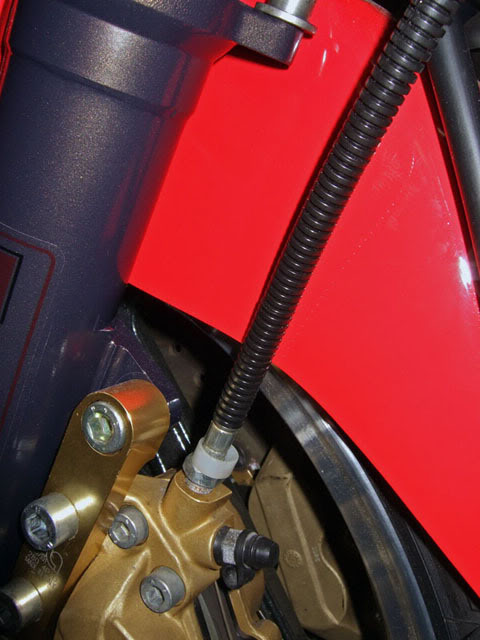

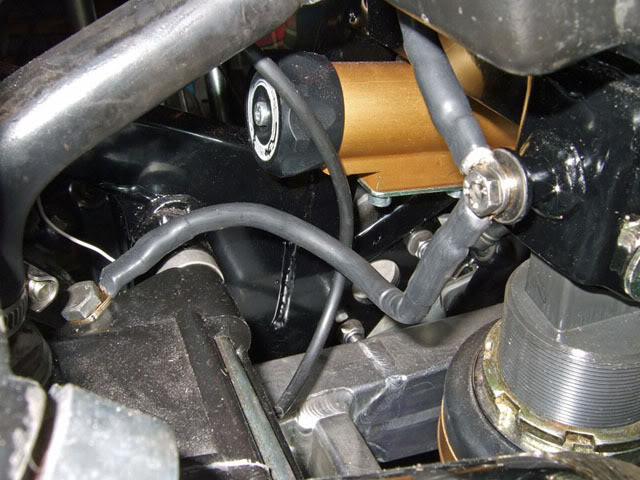

Theoretically a rear floating brake has an advantage compared to one that is fixed to the swingarm (no matter if mounted on top or below). While a brake mounted fix to a swingarm will compress the suspension under braking, making the rear lighter and the tire hop eventually (depending on how hard you hit the brake of course) a floating brake that is connected to the engine should do the opposite. As far as I heard though a floating rear brake sometimes has the tendency to become noisy over time. I have no experiences with this. It`s my first one and I haven`t ridden it yet. Next to wanting to try this it seemed to be the best & most simple solution for my tire/swingarm combo. Actually the only one.