Rear Sprocket bolts all sheared off

-

Mobius

- Posts: 100

- Joined: Thu Jan 21, 2010 2:22 am

- model: 906 Paso

- year: 1990

- Location: Christchurch, New Zealand

Rear Sprocket bolts all sheared off

New Thread for this subject.

As I said in the other thread, after about 100km of open road riding, never above 6000 rpm and always below 120km/h, I lost all drive after a non-powered gear change from 4th to 5th, in an 80km/h zone.

I had stopped at Taitapu 15km beforehand and visually inspected the rear sprocket and chain as I have had some of these bolts loosen before.

Now, the bolts I used were high-tensile, and I also used some "very special" anti-undo washers: two part things with a rachet surface against the sprocket, and each part of the washer has zig-zag surfaces whose angles are greater than the angle of the thread. The idea is that any force applied to them can't undo the bolt because it pulls up harder against the thread than the torque applied to it.

The sales person was very specific, he told me not to over-torque the things ("AS YOU'LL NEVER GET THEM UNDONE!").

Well, I now have the bike at home, but haven't removed the sheared off ends yet. They all snapped in exactly the same place by the look of it, but I have not yet diagnosed whether they really have undone and smashed off on the swingarm, or if the whole lot let go at once.

Once I get them out, I'll be able to see where on the bolts the break happened, and hopefully I can then use that to establish what mode of failure hit me.

Thanks for the posts about the lock-tite and the wired-up-bolts idea - I like both of those. I think I like the wiring idea better, as it means you don't have to check the bolts themselves, as a visual clue is given by the wires. I think this is the approach I'll take.

But I wonder, why on earth does this keep happening? I had four separate instances prior to replacing the bolts and washers where the bolts would undo! I thought the new combination had sorted it - but apparently not.

I have never heard of any such behaviour on any bike, and certainly I never EVER had to tighten sprocket bolts on any previous bike. Is it something to do with the thumpy and lumpy nature of the twin-pot power delivery?

I guess there must be huge pulses of torque travelling down the drive chain, and this must hit the sprocket like a sledge hammer.

As I said in the other thread, after about 100km of open road riding, never above 6000 rpm and always below 120km/h, I lost all drive after a non-powered gear change from 4th to 5th, in an 80km/h zone.

I had stopped at Taitapu 15km beforehand and visually inspected the rear sprocket and chain as I have had some of these bolts loosen before.

Now, the bolts I used were high-tensile, and I also used some "very special" anti-undo washers: two part things with a rachet surface against the sprocket, and each part of the washer has zig-zag surfaces whose angles are greater than the angle of the thread. The idea is that any force applied to them can't undo the bolt because it pulls up harder against the thread than the torque applied to it.

The sales person was very specific, he told me not to over-torque the things ("AS YOU'LL NEVER GET THEM UNDONE!").

Well, I now have the bike at home, but haven't removed the sheared off ends yet. They all snapped in exactly the same place by the look of it, but I have not yet diagnosed whether they really have undone and smashed off on the swingarm, or if the whole lot let go at once.

Once I get them out, I'll be able to see where on the bolts the break happened, and hopefully I can then use that to establish what mode of failure hit me.

Thanks for the posts about the lock-tite and the wired-up-bolts idea - I like both of those. I think I like the wiring idea better, as it means you don't have to check the bolts themselves, as a visual clue is given by the wires. I think this is the approach I'll take.

But I wonder, why on earth does this keep happening? I had four separate instances prior to replacing the bolts and washers where the bolts would undo! I thought the new combination had sorted it - but apparently not.

I have never heard of any such behaviour on any bike, and certainly I never EVER had to tighten sprocket bolts on any previous bike. Is it something to do with the thumpy and lumpy nature of the twin-pot power delivery?

I guess there must be huge pulses of torque travelling down the drive chain, and this must hit the sprocket like a sledge hammer.

How many escape pods are there? "None, Sir!" You counted them? "Twice, Sir!"

- paso750

- paso grand pooh-bah

- Posts: 5560

- Joined: Sun Jul 18, 2004 12:00 am

- model: 750 Paso

- year: 1987

- Location: southern Germany

Re: Rear Sprocket bolts all sheared off

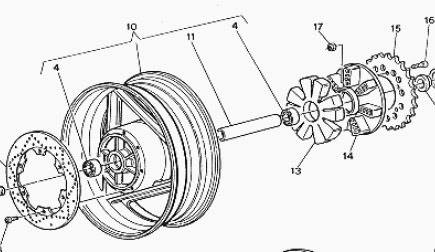

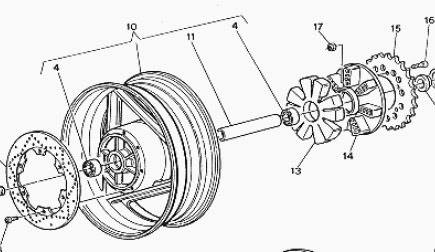

did this already happen with the original tires or only after putting on the 180/60? With the 180 did you offset the sprockets ? If so did you use longer bolts and is the rear sprocket still on the centering edge of the sprocket carrier and do the sprockets align correctly ? In what condition is the rubber damper below the sprocket carrier ?

G.

G.

-

Mobius

- Posts: 100

- Joined: Thu Jan 21, 2010 2:22 am

- model: 906 Paso

- year: 1990

- Location: Christchurch, New Zealand

Re: Rear Sprocket bolts all sheared off

All excellent and relevant questions!

I never did any miles on the original tyres, except to get them replaced.

No, I did not offset the sprocket at all, but after I lost two of the original sprocket bolts due to loosening, I replaced them all. All the alignments seem correct.

I now face the problem of undoing the large hex bolts inside the ex-center. I simply can't budge them to remove the wheel. Today I'm gonna get a pipe to go over the big hex key so I can get more leverage.(I wondered about the condition of the rubber damper also and that's why I want the wheel out.)

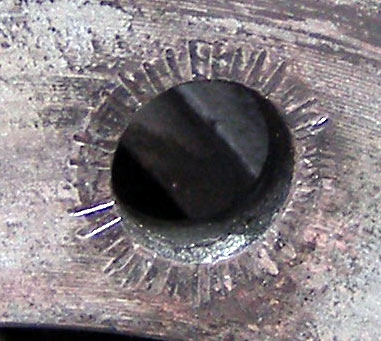

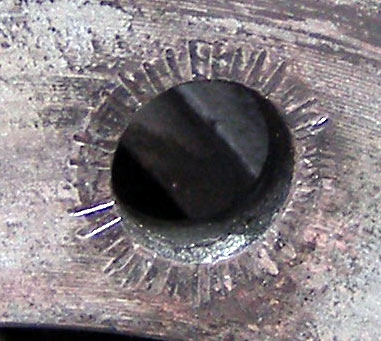

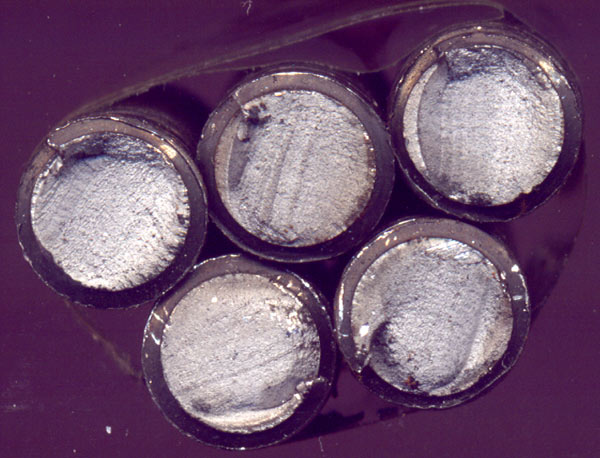

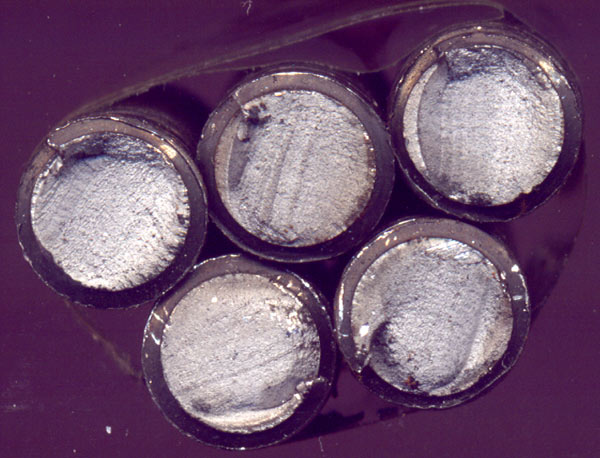

Having removed all the bolts now, I can see they all snapped off right at the end of the thread, which is about 1mm below the head itself, so just the heads are missing. Photo below.

The rachets of the washers I used have created clear markings on the sprocket itself and they are all perfect impressions. In other words, no signs of them having loosened.

What I interpret this to mean is that the bolt heads were simply sheared off. In the position that they were in, they were done up all the way, and have NOT worked their way loose; they've simply snapped off.

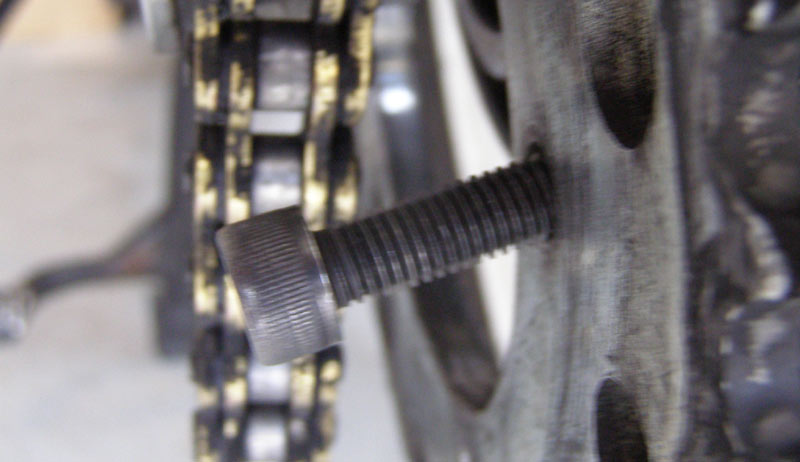

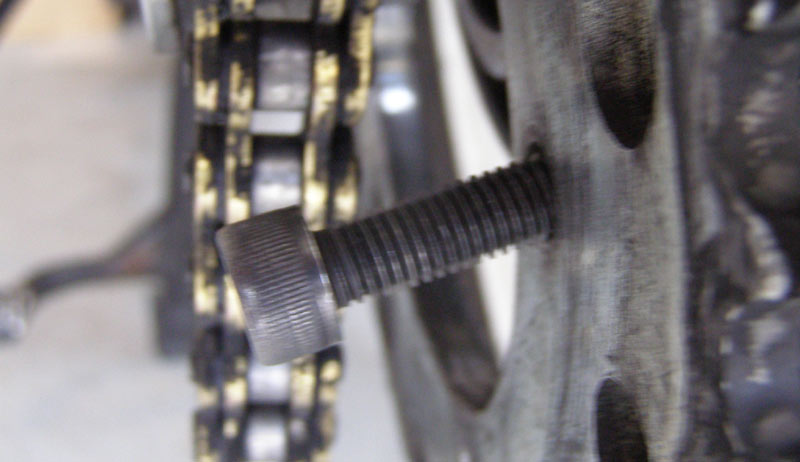

Above you can see the snapped-off bolts. The trailing edge of all the bolts (except one) have very wear on the threads (But not the leading edge which means they have not rotated in position). It's easy to work out why: there is nothing on the back (inboard) side the sprocket which keys into the driving plate it is bolted to.

This means the bolts themselves provide the driving force to the rear wheel, and the only thing holding them in is the tension created by the thread.

This seems to me to be the most stupid possible arrangement! What fool would create such a system? It seems patently obvious to me (and I'm not an an engineer) that the sprocket must have drive points which key into the drive plate, thus, the bolts would only be used to secure the sprocket to the plate, and the driving force would be applied directly to the wheel via the sprocket keys, rather than the bolts.

Of course, now I'm wondering if this is how it is meant to be, and the sprocket I have is some after market thing not intended for use on the Paso.

The sprocket is marked with the following: 238-5/8"

I am certain that if I simply replace these bolts, the exact same thing will happen again, because they have not come undone at all.

I never did any miles on the original tyres, except to get them replaced.

No, I did not offset the sprocket at all, but after I lost two of the original sprocket bolts due to loosening, I replaced them all. All the alignments seem correct.

I now face the problem of undoing the large hex bolts inside the ex-center. I simply can't budge them to remove the wheel. Today I'm gonna get a pipe to go over the big hex key so I can get more leverage.(I wondered about the condition of the rubber damper also and that's why I want the wheel out.)

Having removed all the bolts now, I can see they all snapped off right at the end of the thread, which is about 1mm below the head itself, so just the heads are missing. Photo below.

The rachets of the washers I used have created clear markings on the sprocket itself and they are all perfect impressions. In other words, no signs of them having loosened.

What I interpret this to mean is that the bolt heads were simply sheared off. In the position that they were in, they were done up all the way, and have NOT worked their way loose; they've simply snapped off.

Above you can see the snapped-off bolts. The trailing edge of all the bolts (except one) have very wear on the threads (But not the leading edge which means they have not rotated in position). It's easy to work out why: there is nothing on the back (inboard) side the sprocket which keys into the driving plate it is bolted to.

This means the bolts themselves provide the driving force to the rear wheel, and the only thing holding them in is the tension created by the thread.

This seems to me to be the most stupid possible arrangement! What fool would create such a system? It seems patently obvious to me (and I'm not an an engineer) that the sprocket must have drive points which key into the drive plate, thus, the bolts would only be used to secure the sprocket to the plate, and the driving force would be applied directly to the wheel via the sprocket keys, rather than the bolts.

Of course, now I'm wondering if this is how it is meant to be, and the sprocket I have is some after market thing not intended for use on the Paso.

The sprocket is marked with the following: 238-5/8"

I am certain that if I simply replace these bolts, the exact same thing will happen again, because they have not come undone at all.

How many escape pods are there? "None, Sir!" You counted them? "Twice, Sir!"

- higgy

- paso grand pooh-bah

- Posts: 3337

- Joined: Tue Jul 29, 2008 9:50 pm

- model: 907 I.E.

- year: 1992

- Location: Hilltown,Pennsylvania

- Contact:

Re: Rear Sprocket bolts all sheared off

Just a few observations Mobius,You got me wondering about mine

From the looks of the bolts they appear worn by the sprocket suggesting some part of the assembly was overtightened or more likely stretched/worn to a point where the assembly could not provide the clamping force required to keep this sort of thing from happening.

In my case it was only 2 bolts came out. One day they had been fine,the following day I went out for a quick ride to check on a mod I made,heard a squeek which by the time I noticed and stopped had become a thump thump thump. I now have some nice new scratches in my swing arm as two of the bolts did their level best to shorten the swingarm.

Now to venture a guess, the most likely suspect is the rubber,at best it is 20 to 22 years old

The number two suspect would be the metal used to capture the nuts that hold the whole thing together.

assuming the bolts and nuts went together clean...no grit Hey we are talking about a Ducati

Anyway, I plan to take mine apart over the next few weeks.I have been informed at work our dyne is to be commissioned within the next 9 weeks which gives me 8 weeks to get the 906 ready for the final phase of the Weber/exhaust work,considering the fact that I am currently inundated by snow and ice,indeed not a lot of time.

I will however take some detailed pics so U and I can compare our findings And perhaps save a few Ducatista's a similar fate,sound like a plan?

And perhaps save a few Ducatista's a similar fate,sound like a plan?

G, or any one else with considered experience please feel free to add your thoughts pro or con at anytime

Looking at your pics again,what is on the bolts? is that rubber?

If it is in fact rubber,heat should help you get it apart,if it is any other substance.Got PBX down under?

From the looks of the bolts they appear worn by the sprocket suggesting some part of the assembly was overtightened or more likely stretched/worn to a point where the assembly could not provide the clamping force required to keep this sort of thing from happening.

In my case it was only 2 bolts came out. One day they had been fine,the following day I went out for a quick ride to check on a mod I made,heard a squeek which by the time I noticed and stopped had become a thump thump thump. I now have some nice new scratches in my swing arm as two of the bolts did their level best to shorten the swingarm.

Now to venture a guess, the most likely suspect is the rubber,at best it is 20 to 22 years old

The number two suspect would be the metal used to capture the nuts that hold the whole thing together.

assuming the bolts and nuts went together clean...no grit Hey we are talking about a Ducati

Anyway, I plan to take mine apart over the next few weeks.I have been informed at work our dyne is to be commissioned within the next 9 weeks which gives me 8 weeks to get the 906 ready for the final phase of the Weber/exhaust work,considering the fact that I am currently inundated by snow and ice,indeed not a lot of time.

I will however take some detailed pics so U and I can compare our findings

G, or any one else with considered experience please feel free to add your thoughts pro or con at anytime

Looking at your pics again,what is on the bolts? is that rubber?

If it is in fact rubber,heat should help you get it apart,if it is any other substance.Got PBX down under?

Ducati,making mechanics out of riders since 1946

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

- micklm

- Posts: 103

- Joined: Fri Jun 05, 2009 8:53 pm

- model: 906 Paso

- year: 1989

- Location: Taranaki, New Zealand

Re: Rear Sprocket bolts all sheared off

Mobius,

If you have a good photo of the bolt end on, showing the cross section where it failed, it can be possible to say if the bolts failed in a brittle or ductile fashion. This can help identify the root cause.

One thing I've had problems with before (not on bikes but in my work) with high tensile bolts is if they have been plated by someone and not baked after to remove the hydrogen charged into the steel by the plating process, this can make them brittle. Have the bolts been re-finished or are you aware of their origin?

I agree though, that the damage to the threads around the failure area does point to the bolts backing out and the sprocket being a little loose for some time prior to failure - or was this damage done after the failures while trying to remove the bolts?

Cheers,

Mick

If you have a good photo of the bolt end on, showing the cross section where it failed, it can be possible to say if the bolts failed in a brittle or ductile fashion. This can help identify the root cause.

One thing I've had problems with before (not on bikes but in my work) with high tensile bolts is if they have been plated by someone and not baked after to remove the hydrogen charged into the steel by the plating process, this can make them brittle. Have the bolts been re-finished or are you aware of their origin?

I agree though, that the damage to the threads around the failure area does point to the bolts backing out and the sprocket being a little loose for some time prior to failure - or was this damage done after the failures while trying to remove the bolts?

Cheers,

Mick

906 Paso 1989 w/ 17in wheels

-

Mobius

- Posts: 100

- Joined: Thu Jan 21, 2010 2:22 am

- model: 906 Paso

- year: 1990

- Location: Christchurch, New Zealand

Re: Rear Sprocket bolts all sheared off

Thanks for taking an interest Higgy. The stuff on the bolts is a little lithium grease, and nothing more.

All the bolts went in clean and easy, and bolted down without a problem. They also undid easily when I removed them. (Question, what fool arranges loose nuts behind the drive-plate for the bolts to bolt up into? I had to use a strong magnet to pull two of them far enough outboard for the bolts to screw into!)

The more I look at G's photo of his rear sprocket though, and the retaining bolts, the more I think I have the wrong combination of rear sprocket and retaining bolts. The bolts which have snapped are identical to the bolts I replaced them with.

My rear sprocket has a totally different appearance to the one G displayed. Lemme get some photos real quick...

Here's a hole in the sprocket. You can clearly see the marks left by the super-special-never-undo washers I used. No sign of it having come undone at all. The other holes are the same.

Here's a bolt completely through the sprocket bolt hole. Note the non-snug fit here. The hole is about 1mm wider then the bolt.

Here's the outboard face of my sprocket. It's marked 238-5/8"

Here's the inner face of the sprocket. Clearly shown is the "lip" (about 2mm or so) on the inboard face of the sprocket. Also note the complete absence of any mechanism to transfer the power to the wheel, on the inner face. That can't be right - can it???

Any and all input greatly appreciated.

All the bolts went in clean and easy, and bolted down without a problem. They also undid easily when I removed them. (Question, what fool arranges loose nuts behind the drive-plate for the bolts to bolt up into? I had to use a strong magnet to pull two of them far enough outboard for the bolts to screw into!)

The more I look at G's photo of his rear sprocket though, and the retaining bolts, the more I think I have the wrong combination of rear sprocket and retaining bolts. The bolts which have snapped are identical to the bolts I replaced them with.

My rear sprocket has a totally different appearance to the one G displayed. Lemme get some photos real quick...

Here's a hole in the sprocket. You can clearly see the marks left by the super-special-never-undo washers I used. No sign of it having come undone at all. The other holes are the same.

Here's a bolt completely through the sprocket bolt hole. Note the non-snug fit here. The hole is about 1mm wider then the bolt.

Here's the outboard face of my sprocket. It's marked 238-5/8"

Here's the inner face of the sprocket. Clearly shown is the "lip" (about 2mm or so) on the inboard face of the sprocket. Also note the complete absence of any mechanism to transfer the power to the wheel, on the inner face. That can't be right - can it???

Any and all input greatly appreciated.

How many escape pods are there? "None, Sir!" You counted them? "Twice, Sir!"

- higgy

- paso grand pooh-bah

- Posts: 3337

- Joined: Tue Jul 29, 2008 9:50 pm

- model: 907 I.E.

- year: 1992

- Location: Hilltown,Pennsylvania

- Contact:

Re: Rear Sprocket bolts all sheared off

Lithium grease? Hmmm.maybe you did this to yourself.....Rubber parts generally can't handle petroleum or silicone grease of any kind (Although silicone grease is OK in some limited situations depending on the rubber composition) and should be assembled dry,the only acceptable lubricant would be water and even then only if it can evaporate in free air..............JM2C.....will still look into mine so we can compare

BTW,the rubber is the intended transfer of torque part of the equation

BTW,the rubber is the intended transfer of torque part of the equation

Ducati,making mechanics out of riders since 1946

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

-

Mobius

- Posts: 100

- Joined: Thu Jan 21, 2010 2:22 am

- model: 906 Paso

- year: 1990

- Location: Christchurch, New Zealand

Re: Rear Sprocket bolts all sheared off

Thanks Mick.

Massive image: http://4sure.co.nz/paso/paso-bolts-broken.jpg

This is what I think happened: because there is no mechanism to transfer force to the wheel other than the bolts, the power of the engine loads the sprocket up so that it tries to rotate somewhat. The bolts prevent it rotating more than the width of the spare space between the bolts and the sprocket (The holes in the sprocket).

This starts wearing the threads on one side (My bolts only show wear on one side) which increases the free play, which accentuates the rotation the sprocket can achieve, even when done up tight.

Eventually the bolts fail at their weakest point, which is where the thread starts, just below the bolt head.

Can someone comment please about attempting to transfer 88 BHP through 5 bolts AND NOTHING ELSE?

Here you go. This is a small image. Links to huge image below it.micklm wrote:If you have a good photo of the bolt end on, showing the cross section where it failed, it can be possible to say if the bolts failed in a brittle or ductile fashion. This can help identify the root cause.

Massive image: http://4sure.co.nz/paso/paso-bolts-broken.jpg

I purchased form a reputable outlet which specialises in fasteners. They said they were high tensile. But I will return to them and query them further: I still have two new ones I got as spares.micklm wrote:Have the bolts been re-finished or are you aware of their origin?

The bolts came out easily using a pair of pliers with very little force applied. The damage you see to the thread was caused in situ by the sprocket itself, and the bolts, I am feeling very confident did NOT undo prior to failure. Or if they did, it could only have been by a very small amount, because I had to undo the bolts an equal amount, and a visual inspection shows that the amount I had to undo them is the exact same amount as when I did them up.micklm wrote:I agree though, that the damage to the threads around the failure area does point to the bolts backing out and the sprocket being a little loose for some time prior to failure - or was this damage done after the failures while trying to remove the bolts?

This is what I think happened: because there is no mechanism to transfer force to the wheel other than the bolts, the power of the engine loads the sprocket up so that it tries to rotate somewhat. The bolts prevent it rotating more than the width of the spare space between the bolts and the sprocket (The holes in the sprocket).

This starts wearing the threads on one side (My bolts only show wear on one side) which increases the free play, which accentuates the rotation the sprocket can achieve, even when done up tight.

Eventually the bolts fail at their weakest point, which is where the thread starts, just below the bolt head.

Can someone comment please about attempting to transfer 88 BHP through 5 bolts AND NOTHING ELSE?

How many escape pods are there? "None, Sir!" You counted them? "Twice, Sir!"

-

Mobius

- Posts: 100

- Joined: Thu Jan 21, 2010 2:22 am

- model: 906 Paso

- year: 1990

- Location: Christchurch, New Zealand

Re: Rear Sprocket bolts all sheared off

That's not how my bike was setup. If you look at the photos, the only mechanism which locates the sprocket is 5 bolts. Nothing more. Therefore it is the BOLTS which transfer the torque to the wheel. The rubber may smooth the delivery of the torque, but is not responsible for connecting the sprocket to the wheel. It seems very wrong to me.higgy wrote:BTW,the rubber is the intended transfer of torque part of the equation

How many escape pods are there? "None, Sir!" You counted them? "Twice, Sir!"

-

Mobius

- Posts: 100

- Joined: Thu Jan 21, 2010 2:22 am

- model: 906 Paso

- year: 1990

- Location: Christchurch, New Zealand

Re: Rear Sprocket bolts all sheared off

I should explain more clearly. When I fitted the bolts I placed about 1mm cubed of lithium grease on the end of the bolt. An infinitesimally small amount.higgy wrote:Lithium grease? Hmmm.maybe you did this to yourself...

I have now inspected the gunk in the threads of the broken bolts, and it appears to be an amalgam of shredded metal fibres of very small size and perhaps some rubber or greasy substance. If I roll it between my fingers it yields tiny slivers and particles of metal within it. This would seem to be consistent with with erosion of the trailing thread as the sprocket pushes against it.

I have not yet been able to undo the ex-center Hex bolts, so I can't remove the the wheel to inspect the rubber. I will try todo that later today.

Can someone advise how to get the axle out? The manual simply says "use a special tool".

How many escape pods are there? "None, Sir!" You counted them? "Twice, Sir!"

- paso750

- paso grand pooh-bah

- Posts: 5560

- Joined: Sun Jul 18, 2004 12:00 am

- model: 750 Paso

- year: 1987

- Location: southern Germany

Re: Rear Sprocket bolts all sheared off

Mobius, you`re mistaking, Take a look at the parts manual. The sprocket is mounted to a sprocket carrier. The sprocket carrier sits in the pan that`s mounted to the rim. Behind the sprocket carrier there`s the rubber damper. You cannot see it if you don`t remove the sprocket carrier. This is the point where the power is transferred from the sprocket to the wheel.

The bolts don`t take the driving force. If there wasn`t a centering lip to the sprocket carrier and/or the bolts where loose full (shearing) force would go on the bolts but that`s not the case. The holes in the sprocket are not bigger than the bolts meaning that when you tighten them the sprocket should not be able to slip.

Thinking about it the clutch is not that much different. There`s a force closure/frictional connection that`s held up only by 6 little springs

I wonder about the inner lip of the sprocket. Mine has a lip too, it`s where the bolts are sunk in. Could it be that your`s is also like that but mounted reverse ?! Maybe to give more tire-chain clearance with the 180 ? In that case the chain would be out of line causing more stress/wear on the sprockets, bolts and the chain itself. (but I`d expect that to show in wear over time and not snapped bolts)

G.

The bolts don`t take the driving force. If there wasn`t a centering lip to the sprocket carrier and/or the bolts where loose full (shearing) force would go on the bolts but that`s not the case. The holes in the sprocket are not bigger than the bolts meaning that when you tighten them the sprocket should not be able to slip.

A wheel from a car is also only fixed with 5 M10 bolts no matter if it has 70hp or 600. I don`t know the correct english/technical terms but the bolts create a contact pressure between sprocket and carrier (or car wheel and hub). This is what actually tranfers the forces. I`m not a technician so someone correct me.Can someone comment please about attempting to transfer 88 BHP through 5 bolts AND NOTHING ELSE?

Thinking about it the clutch is not that much different. There`s a force closure/frictional connection that`s held up only by 6 little springs

I wonder about the inner lip of the sprocket. Mine has a lip too, it`s where the bolts are sunk in. Could it be that your`s is also like that but mounted reverse ?! Maybe to give more tire-chain clearance with the 180 ? In that case the chain would be out of line causing more stress/wear on the sprockets, bolts and the chain itself. (but I`d expect that to show in wear over time and not snapped bolts)

If a sprocket is replaced the rear wheel and the sprocket carrier are removed. Normally noone would remove the bolts when everything is assembled correctly. I guess that`s the simple thinking behind that.(Question, what fool arranges loose nuts behind the drive-plate for the bolts to bolt up into? I had to use a strong magnet to pull two of them far enough outboard for the bolts to screw into!)

G.

- higgy

- paso grand pooh-bah

- Posts: 3337

- Joined: Tue Jul 29, 2008 9:50 pm

- model: 907 I.E.

- year: 1992

- Location: Hilltown,Pennsylvania

- Contact:

Re: Rear Sprocket bolts all sheared off

Mobius

Just to clarify All the bolts do here or in the case G presented with a wheel, is provide the clamping force. They are in no way intended to be involved in torque transfer beyond clamping the parts, it is the friction between the material they clamp together that does the duty of torque transfer

In this case even a small amount of lithium grease will allow the rubber to slip making the bolts do the job of torque transfer,something for which they are not designed to do

The thing I find odd here is that they appeared to have sheared on the outside plane of the sprocket,On first impression I would have thought they would shear on the inside of the sprocket

Just to clarify All the bolts do here or in the case G presented with a wheel, is provide the clamping force. They are in no way intended to be involved in torque transfer beyond clamping the parts, it is the friction between the material they clamp together that does the duty of torque transfer

In this case even a small amount of lithium grease will allow the rubber to slip making the bolts do the job of torque transfer,something for which they are not designed to do

The thing I find odd here is that they appeared to have sheared on the outside plane of the sprocket,On first impression I would have thought they would shear on the inside of the sprocket

Ducati,making mechanics out of riders since 1946

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

Re: Rear Sprocket bolts all sheared off

I'm not trying to be critical of your workmanship but I can see a couple of problems here.

One should always replace the lock nuts when fitting new bolts. How many bolts have you replaced without changing the nuts?Mobius wrote: (Question, what fool arranges loose nuts behind the drive-plate for the bolts to bolt up into? I had to use a strong magnet to pull two of them far enough outboard for the bolts to screw into!)

You only apply grease to bolts to stop corrosion and if you want to prevent the threads from galling. The correct option would be to use lock-tite. It also stops the threads from galling and prevents corrosion.Mobius wrote: I should explain more clearly. When I fitted the bolts I placed about 1mm cubed of lithium grease on the end of the bolt. An infinitesimally small amount.

No matter how much you tighten the bolts the sprocket will always rotate until the free play has taken up. It will not only do it once, but every time the power is brought on. This has the effect of stretching the bolt over and over until it comes loose or reaches it's tensile limit and breaks. (G, the wheel nuts on a car have a chamfer on them to stop this.) Have a look at the bolt holes in the sprocket carrier to see if they are starting to flog out, which I suspect is happening as well, this will only exaggerate the problem.Mobius wrote:This is what I think happened: because there is no mechanism to transfer force to the wheel other than the bolts, the power of the engine loads the sprocket up so that it tries to rotate somewhat. The bolts prevent it rotating more than the width of the spare space between the bolts and the sprocket (The holes in the sprocket).

This starts wearing the threads on one side (My bolts only show wear on one side) which increases the free play, which accentuates the rotation the sprocket can achieve, even when done up tight.

Eventually the bolts fail at their weakest point, which is where the thread starts, just below the bolt head.

Can someone comment please about attempting to transfer 88 BHP through 5 bolts AND NOTHING ELSE?

-

Mobius

- Posts: 100

- Joined: Thu Jan 21, 2010 2:22 am

- model: 906 Paso

- year: 1990

- Location: Christchurch, New Zealand

Re: Rear Sprocket bolts all sheared off

OK, excellent contributions here, thanks very much people!

Yes, I now understand that friction on the sprocket carrier created by the bolts is what is supposed to carry the force to the wheel. It still seems like a very poor design however. In my view the sprocket should have shaped lugs which insert into the sprocket carrier to transfer 100% of the load. In that scenario there would be zero deflection of the bolts and zero lateral force applied to the bolts.

Yes the bolts sheared off at the outside edge of the sprocket, not the inside, which would seem more likely!

Yes, my sprocket is reversed to gain the extra clearance for the chain. And because this would alter the chain offset I had a chat to a very experienced engineer friend of mine (who also happens to restore old motorcycles) before I initially did it. He says that 2mm over the reach of the Paso chain "is effectively straight". "Trust me", he said, "it will not be an issue, especially with modern chain technology."

So, I without evidence to the contrary, I discount the 2mm offset as being anything to do with this issue.

I did not replace the nuts inside the sprocket carrier when I replaced the bolts, I just assumed they would be fine. (They went in easily).

Far more likely I think, is the sprocket carrier being somewhat damaged (slogged out holes) or the rubber part is minced, or the bolts supplied to me were not of the quality that I stipulated when I purchased them. I hope the later is the case.

I will certainly use lock-tite next time, and the one G recommended in the other thread.

Yes, I now understand that friction on the sprocket carrier created by the bolts is what is supposed to carry the force to the wheel. It still seems like a very poor design however. In my view the sprocket should have shaped lugs which insert into the sprocket carrier to transfer 100% of the load. In that scenario there would be zero deflection of the bolts and zero lateral force applied to the bolts.

Yes the bolts sheared off at the outside edge of the sprocket, not the inside, which would seem more likely!

Yes, my sprocket is reversed to gain the extra clearance for the chain. And because this would alter the chain offset I had a chat to a very experienced engineer friend of mine (who also happens to restore old motorcycles) before I initially did it. He says that 2mm over the reach of the Paso chain "is effectively straight". "Trust me", he said, "it will not be an issue, especially with modern chain technology."

So, I without evidence to the contrary, I discount the 2mm offset as being anything to do with this issue.

I did not replace the nuts inside the sprocket carrier when I replaced the bolts, I just assumed they would be fine. (They went in easily).

Far more likely I think, is the sprocket carrier being somewhat damaged (slogged out holes) or the rubber part is minced, or the bolts supplied to me were not of the quality that I stipulated when I purchased them. I hope the later is the case.

I will certainly use lock-tite next time, and the one G recommended in the other thread.

How many escape pods are there? "None, Sir!" You counted them? "Twice, Sir!"

- higgy

- paso grand pooh-bah

- Posts: 3337

- Joined: Tue Jul 29, 2008 9:50 pm

- model: 907 I.E.

- year: 1992

- Location: Hilltown,Pennsylvania

- Contact:

Re: Rear Sprocket bolts all sheared off

So, I without evidence to the contrary, I discount the 2mm offset as being anything to do with this issue.

Hmmm,not to be contrary but moving the line of force away from the clamping force of the bolts will in fact add stress on the bolts themselves. It would also explain why they sheared on the outside of the sprocket

Ducati,making mechanics out of riders since 1946

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie

There's no problem so bad that a little fixing can't make it worse! : )

If it ain't broke keep fixin it till it is

88 750

90 906

92 907ie